Vertical Silicone Rubber Vulcanization Line.

Mitsuba Mfg. Co. Ltd. has a silicone rubber vulcanization line that can continuously produce tubes and profile products used in these fields from extrusion to vulcanization according to the size and shape of the product.

We have two types of manufacturing equipment: a horizontal silicone rubber vulcanization line (horizontal extrusion) and vertical silicone rubber vulcanization line (upward extrusion).This page introduces the vertical silicone rubber vulcanization line.

Product Features

【Features】

As the work extruded upward is vulcanized without contact. There are no marks on the belt or guide roll.Since vulcanization is performed with the shape extruded from the head, crushing and deformation due to the product’s own weight are minimized.

【Suitable product】

- Thin-walled products that may be crushed or deformed due to their own weight.

- Deformed product with rough part on the work surface.

- Tube with strict roundness.

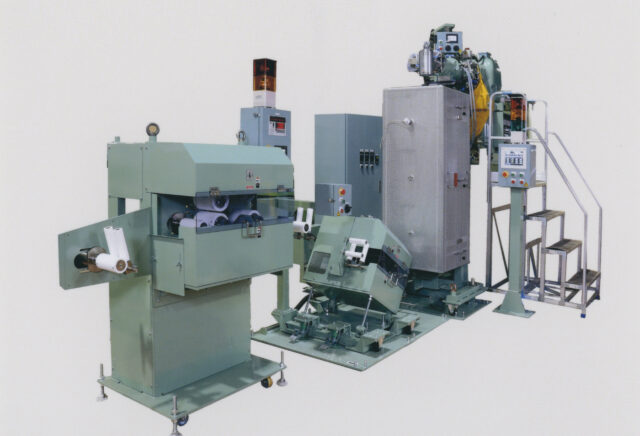

1.Silicone Rubber Extruder

- ・With a rich Line-up of screw sizes from 20㎜~120㎜, so you can choose according to your production conditions. Vent type is also available for each size of 30 mm or more.

- ・Multi-layer extrusion such as two-layer or three-layer is also available.

- ・If the silica content is high, various wear-resistant materials can be selected for the screws and cylinders.

- ・We have taken measures against coloring by metal touch.

- ・For silicone rubber, which has a fast cross-linking reaction, we also have a screw shape for low-temperature extrusion that suppresses shear heat generation in the cylinder.

2. Supply equipment

- You can provide extruder with ribbon that optimum width automatically, only input B mixed block added vulcanization materials by means of open-roll or pressure needer by customers at the last time.

reduce processes manual cutting tailored to injection sizes of materials, worker’s waiting time by injection part lead worker-saving.

Safe Measures

It can install nitrogen gas generate machine (option) to inside of furnace as fire measure.

Ancillary equipment

We have prepared ancillary equipment to meet various requirements, such as a winding machine for drums for long products and a cutting machine for cutting short products to a fixed size, according to the next process and shipping form of the vulcanized product.

2-2.Vertical Vulcanizer

- Curing surface close to inlet side of vulcanization furnace (underside) by using far-infrared heater 500 degrees C on furnace atmosphere temperature minimize break and stretch of products.

- We adopted cylindrical heater for stabilize distance between work and heater as

- By using a cluster roller type take-up mechanism, it absorbs the elongation due to expansion during vulcanization and foaming

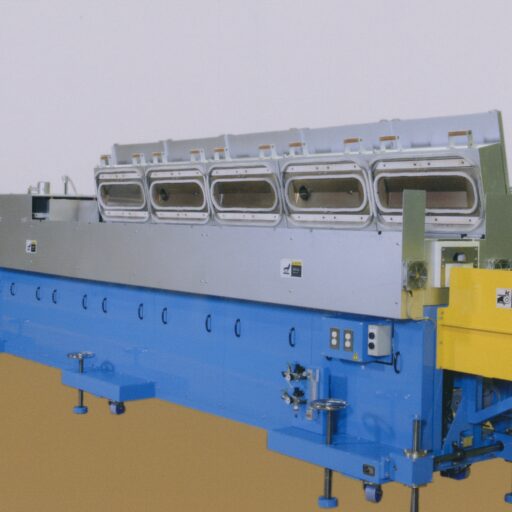

2-3.Horizontal vulcanizer

- We propose a method suitable for vulcanization conditions from two types, a far-infrared heater type and a HAV method that uses a hot air generator.

[Infrared heater type]

Since configurable furnace atmosphere temperature high at 500 degrees C promote vulcanization reaction and it leads faster line speed.

[HAV方式]

Furnace temperature is low up to 230 degrees C, but it suit sponge products need uniformity of cell because it can uniform heating work surface by air as heat medium. - Conveying such as thin products and hollow products which have low take-over tension on endless-belt installed in furnace.

3.LCM Vulcanizer

As vulcanization method using molten salt as a catalyst doesn’t exposure to air, also can use effectively for vulcanization using peroxide vulcanizing agent.

There are features less generated gas compare to other methods(UHF, HAV, PCM) and less oxidization, deterioration by vulcanization without exposure to air.

Since heating medium is liquid, make temperature control easy and also it’s capable of unform temperature rising entire work circumference.