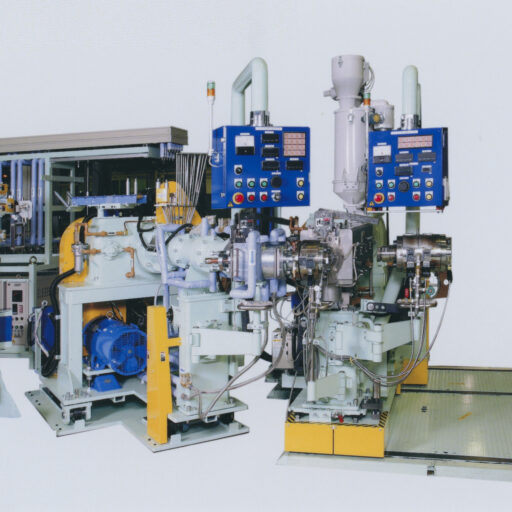

1 Deck Type Spiral Machine

Used for the manufacture of hoses that require strength and durability,

our spiral machines are designed to accommodate the use of mandrels.

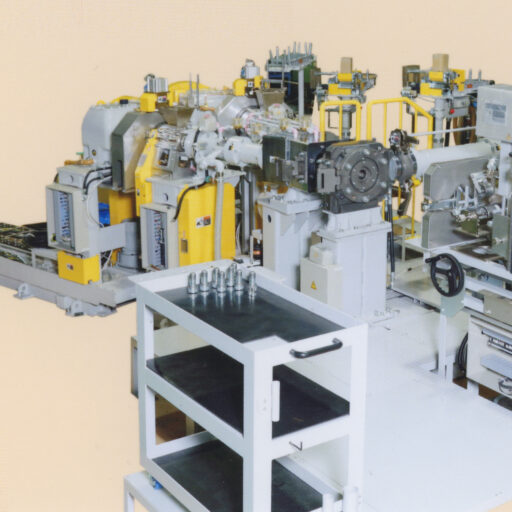

For non-mandrel type spiral hose manufacturing lines, we offer inline type spiral machines that meet the most demanding requirements in terms of high speed and large-scale bobbins (spools). We also have braiding machines that extrude hoses in the tube + braid + cover formation without the use of mandrels.

our spiral machines are designed to accommodate the use of mandrels.

For non-mandrel type spiral hose manufacturing lines, we offer inline type spiral machines that meet the most demanding requirements in terms of high speed and large-scale bobbins (spools). We also have braiding machines that extrude hoses in the tube + braid + cover formation without the use of mandrels.

Product Features

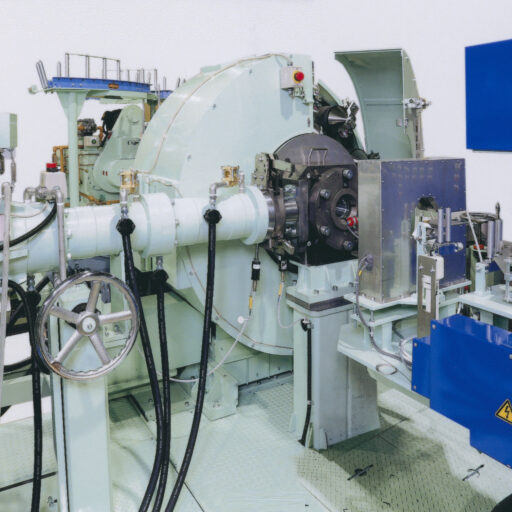

Deck Type Spiral Machine

A spiral machine that can handle a maximum rotation of 1200rpm and can also be equipped with a large-capacity bobbin.

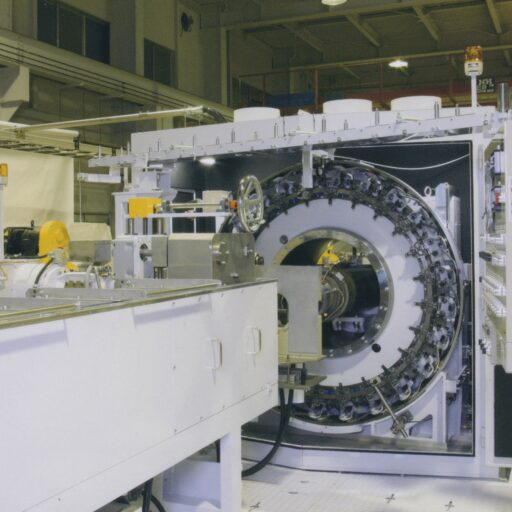

Tension Adjustment Unit

Torque roller type or spring type can be selected.

The torque roller type can set a wider range of tension than the spring type.

In addition, tension adjustment time can be shortened because tension can be controlled by setting the torque roller.

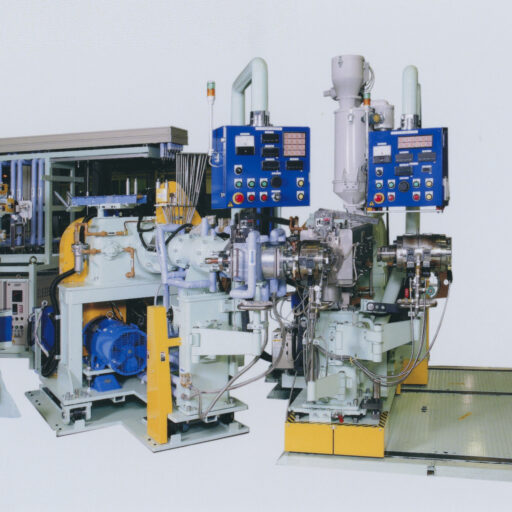

Thread Remaining Volume(Quantity) Management System

A large volume of yarn is discarded to prevent hose failure due to reinforcing yarn breakage.

The reinforcing yarn remaining volume management system developed by Mitsuba can manage the volume of yarn to be discarded to the minimum, and can greatly improve the cost.