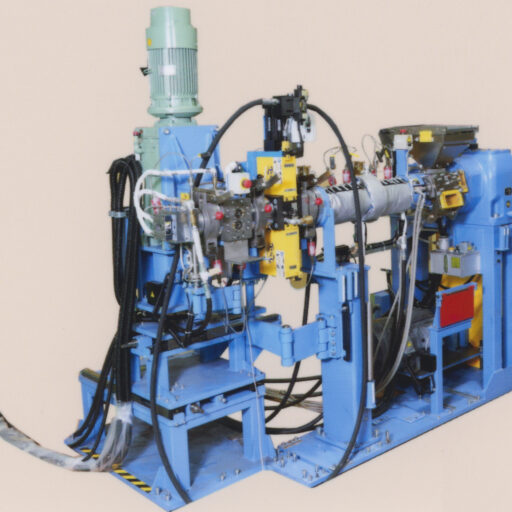

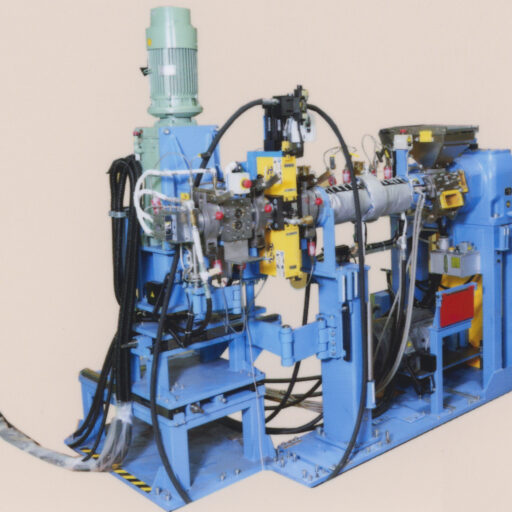

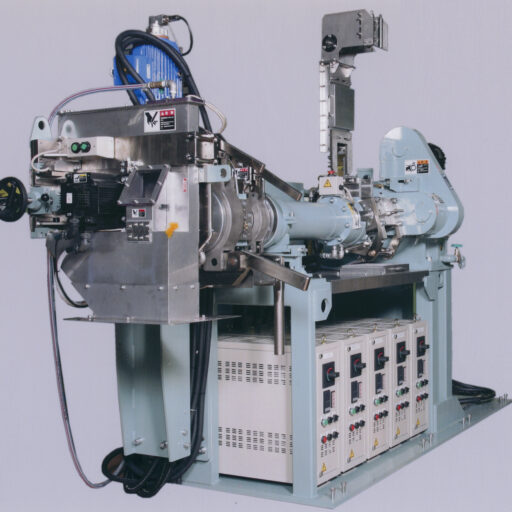

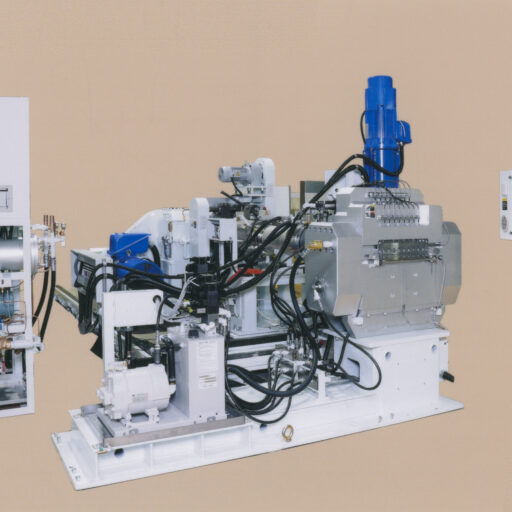

Gear Pump with RMR

If heating or kneading are not needed such as putting the rubber kneaded by calender roll into the gear pump directly in hot feed state, there is RMR (rolling mill roll) method that puts the rubber into the gear pump with two rolls instead of the extruder.

Product Features

Since Gear pump with RMR doesn’t use the extruder, it has advantages such as space saving, energy saving and reducing material loss.

The hydraulic opening/closing mechanism between the gear pump and RMR is available as an option. It is useful for improving cleaning and maintenance work of the larger gear pump.