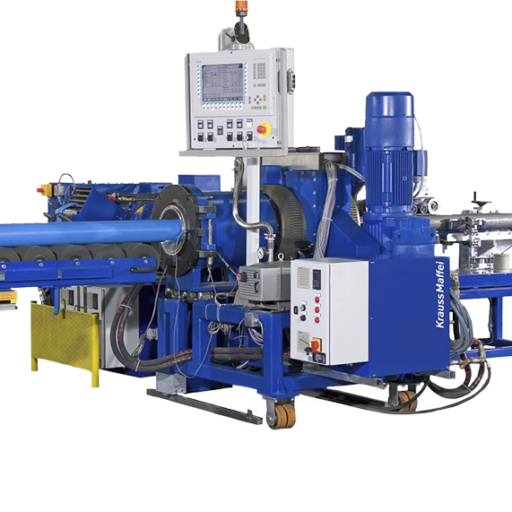

Strip-Winding type roll manufacturing device

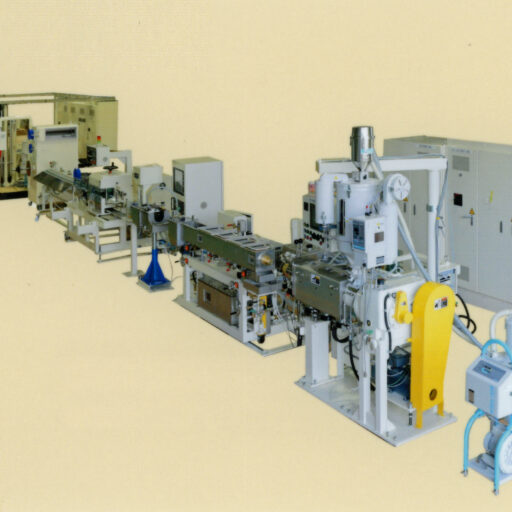

Strip winding is a production method used in a wide range of applications, especially suitable for the forming of rolls with large diameters and lengths.

This roll production system is used throughout the world for rolls in the steel industry and paper production.

Homogenous strips are output from the die thanks to extruder technology accumulated over many years, helping to provide unmatched quality.

This roll production system is used throughout the world for rolls in the steel industry and paper production.

Homogenous strips are output from the die thanks to extruder technology accumulated over many years, helping to provide unmatched quality.

Product Features

- Flexible use of different KraussMaffei high-performance extruders

- Straight-through head with optimized flow channels and exchangeable final dies Optional: Mini-roller head for the manufacture of high-quality rubber strips and higher covering speeds

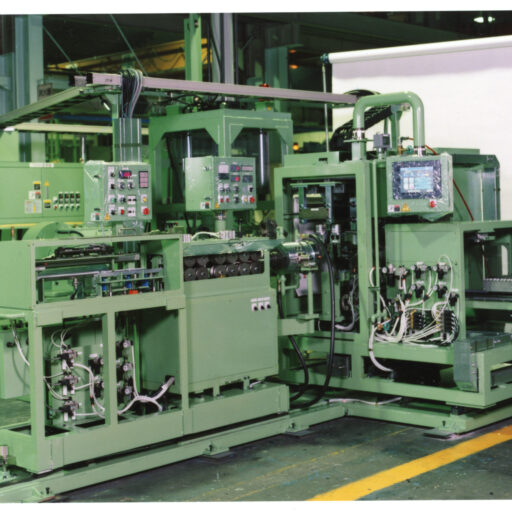

- In-line straining of the compound

- Smooth and precise base frame drive

- Fully automatically controlled travel for straight or inclined application

- Simple operation from a central panel

- Low manning requirement

- Short production times

- Highly accurate covering thickness

- Effective avoidance of air inclusions when covering

- State-of-the-art controls with PLC and operator panel

- Storage possibility for production and process data (recipes)

- Direct or graphic display of all relevant data in set/actual form