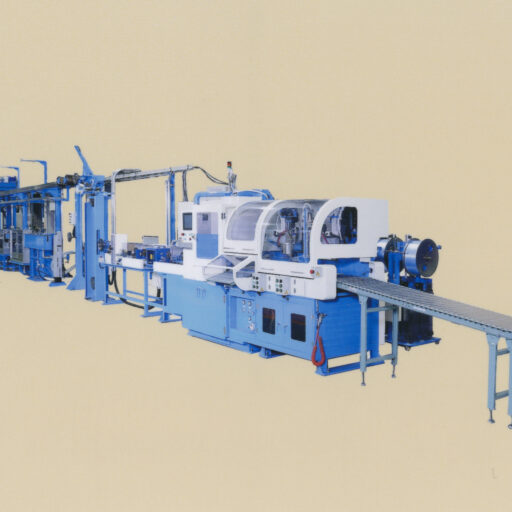

One-Step Silane Cross-Linking CV Line

Polyethylene cables have excellent insulating properties, but they have the weakness of deforming when heated.

It is already well known that this weak point can be improved by increasing the intermolecular bond by means of cross-linking.

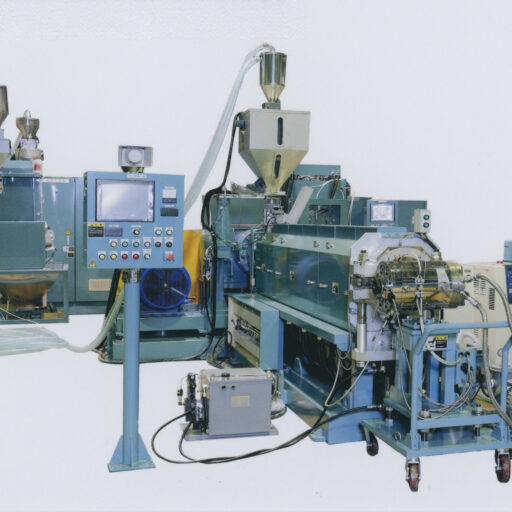

In this section, Mitsuba would like to introduce a one-step silane cross-linking CV line that uses silane injection developed independently by our company.

Significant improvements can be expected in terms of facilities, processes and materials compared to the conventional two-step method.

We have incorporated our latest technology in every device other than the extruder, such as the control surface and so forth. In this sense we have a wide variety of products. Mitsuba believes to be able to provide a line that meets the needs of your requirements. Please consult us for any.

※In addition, we can also handle a tandem line in which the insulation process and the sheathing process become to a series of lines.。

It is already well known that this weak point can be improved by increasing the intermolecular bond by means of cross-linking.

In this section, Mitsuba would like to introduce a one-step silane cross-linking CV line that uses silane injection developed independently by our company.

Significant improvements can be expected in terms of facilities, processes and materials compared to the conventional two-step method.

We have incorporated our latest technology in every device other than the extruder, such as the control surface and so forth. In this sense we have a wide variety of products. Mitsuba believes to be able to provide a line that meets the needs of your requirements. Please consult us for any.

※In addition, we can also handle a tandem line in which the insulation process and the sheathing process become to a series of lines.。

Product Features

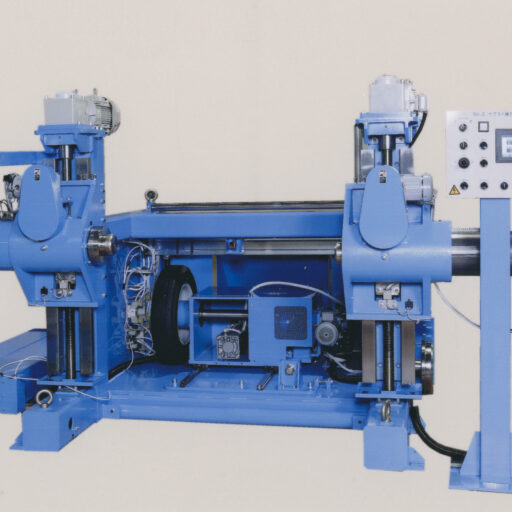

1.One-Step Silane Cross-Linking Extruder

- The silane injection developed by our company can be linearly supplied to the extruder even if the number of rotations is increased, without any variation in the discharge of the silane cocktail material.

- Cylinder: A grooved liner is used under the hopper to stably push the resin pellets with the silane cocktail attached to the tip of the cylinder without slipping.

In addition, the groove shape is such that the silane cocktail does not easily remain in the groove.

Screw: A special shape is used to evenly mix the silane cocktail and resin pellets.

- Since stable temperature control is required for a uniform cross-linking reaction, the heating and cooling method for each zone is selected by using the hot oil circulation type or the electric heater + blower type.

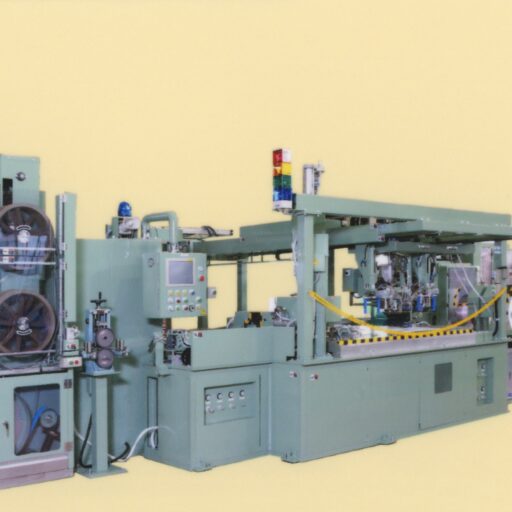

2.Cross head

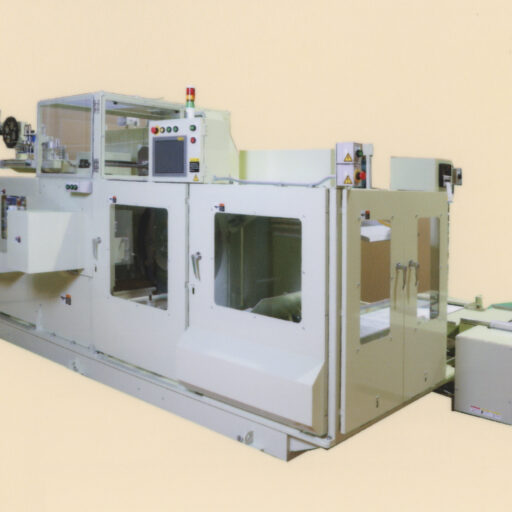

3.Preheater

- As the three-phase power supply is converted to direct current internally, the reactive power is small therefore the running cost is economical.

- Since the line heating speed is controlled from the line speed of 20 m/min and the heating temperature of the wire is controlled, the loss of wire can be reduced because it can be produced at the same quality as the normal production speed at startup and shutdown.

In addition, it constantly monitors the environmental temperature and automatically follows the temperature changes in the summer and winter without changing the setting.

- By using 800Hz high-frequency trans enables whole unit to be compact and installation at the least space

- By setting the wire size, line speed, and temperature conditions on the touch panel, operation can be started without making fine adjustments during production.

Also, by calling the conditions registered in the recipe screen, reproducible operation can be started in a short time regardless of the skill of the worker.

- The non-contact type disconnection detector is equipped on the input line and the air clamp mechanism is equipped on the output line, which is useful for disconnection.

- From the viewpoint of safety and machine protection, various heating interlocks and anomaly detection functions are provided to enhance the control functions.

- Paint color, front door opening and closing direction, caster wheel type (standard) or rail moving type (option) can be selected.

※The function of the device is a standard specification, so we cannot design and manufacture it according to customer request.

- As standard, the internal program controls the current corresponding to the wire size based on the resistance value of copper so that the conductor surface temperature can be heated close to the set value. However, since the actual conductor surface temperature is not controlled, if the conductor is not 100% copper or tin plated, the electrical resistance value changes and error occurs.

Also, due to heat dissipation, the temperature will be lower than the set value depending on the wire size and line speed.

By providing feedback control with a non-contact type thermometer as an option, it is possible to produce under temperature conditions closer to the set value.