PVC and TPO sheet extrusion

In particular, TPO is an elastomer (elastic body) at room temperature, and is a unique synthetic resin that can be molded in the same way as general plastic while having rubber-like properties. Recently, it is a material that can be expected to grow in future so as to adopt such as being used in automobile parts.

Product Features

- PVC and TPO are used not only for roof membranes, waterproof pools, dams, canals, and reservoirs, but also for the roofs of ordinary houses these days. Other examples of use include industrial buildings, warehouses, exhibition halls, administrative facilities, and multi-story parks.

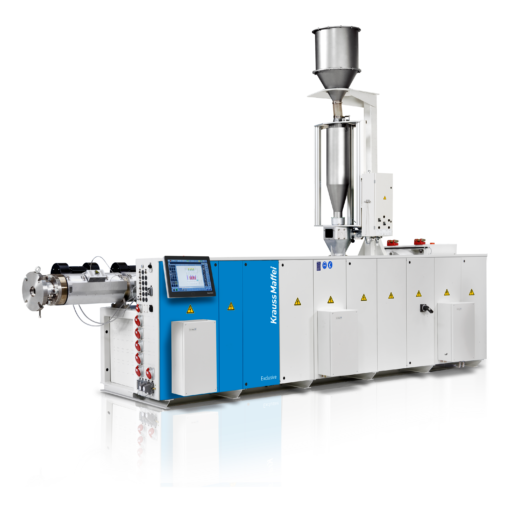

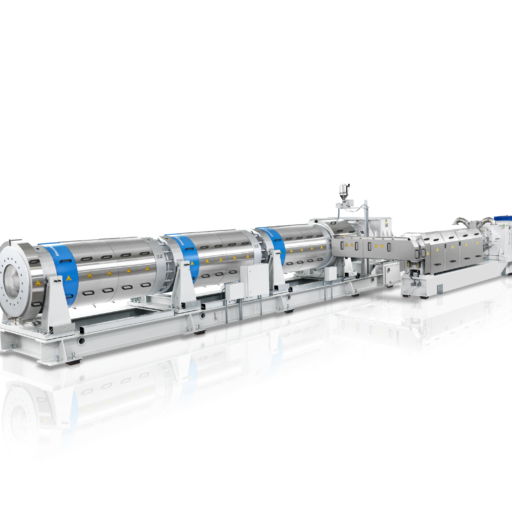

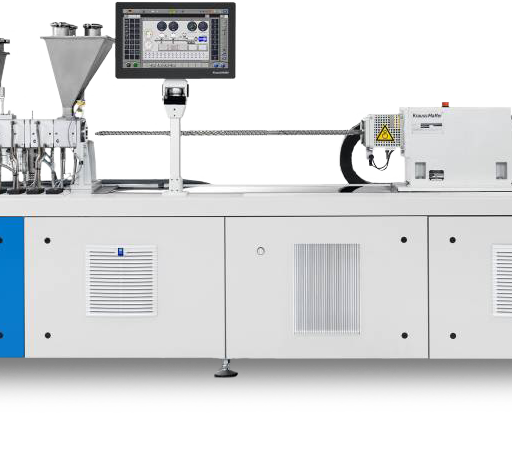

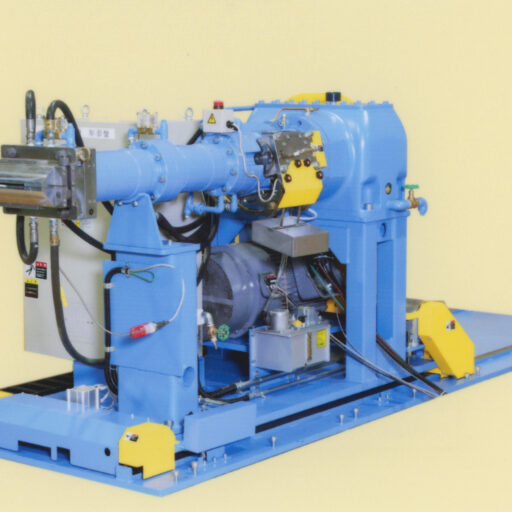

- As a roof membrane production equipment manufacturer, KME is a top company in the world, supplying not only extruders alone but also system solutions and customer-made turnkeys.

- Compared to normal black roof membranes, PVC and TPO can be selected to be white, which enables heat diffusion and leads to great energy savings.

- The operating environment temperature is also used in a wide range from -40 °C to + 70 °C, and it is used in countries all over the world.

- Membranes need to pass international ignition resistance standards, but both PVC and TPO are well suited to this demand as modern construction materials.

- In terms of productivity, the KME extrusion line can achieve a high discharge rate of up to 5t/h. (In-line compounding by optimal design of twin-screw extruder)

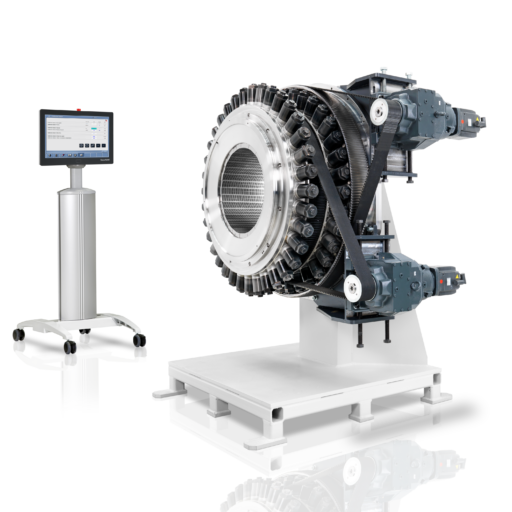

- A Twin screw in the same direction is mainly used for dispensing TPO materials, which is suitable for material homogenization.

- KME has debuted a different direction rotating twin-screw extruder, which is a perfect facility for materials that are sensitive to heat and mechanical kneading stress, such as PVC.