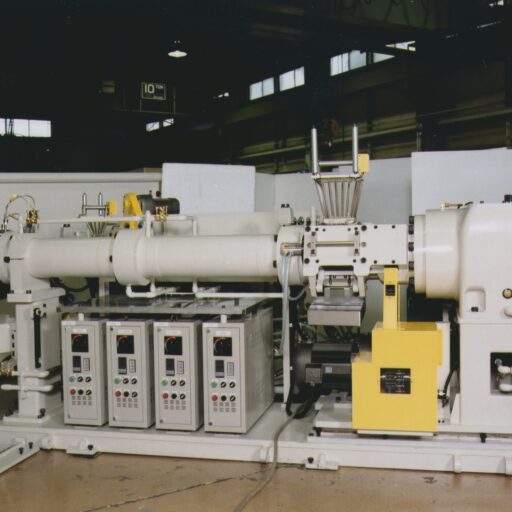

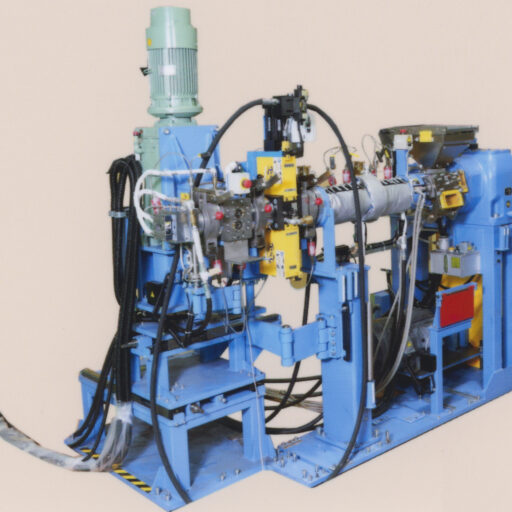

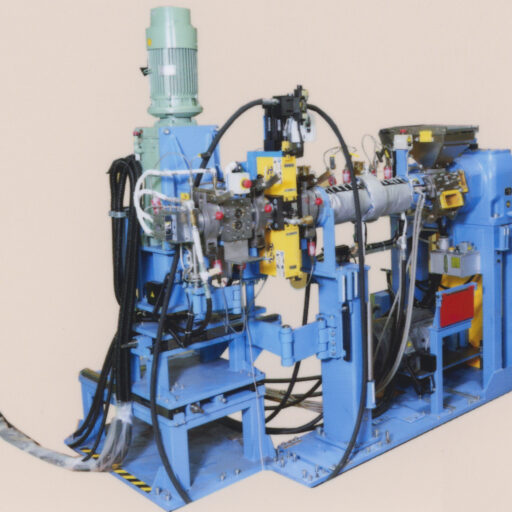

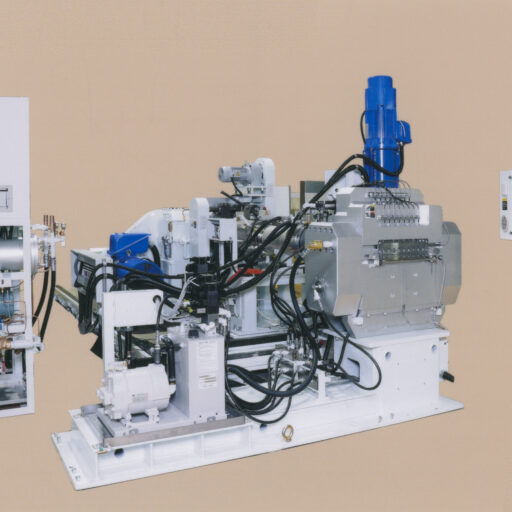

Pin Type Rubber Extruder

Concerning the pin type extruder, dozens of pins are projected from the cylinder toward the center of the screw, and the flight part of the screw is grooved in the circumferential direction so as to avoid interference with the pins which allow the pins to pass through.

By means of attaching pins, many effects can be obtained.

・The pin immediately after the feed zone increases the coefficient of friction between the cylinder liner and the cold rubber compound, changing the ratio of the axial and circumferential flow of the rubber. This increases the carrying capacity of the screw.

・At the center of the pin cylinder where the rubber compound is heated, the rubber flow is divided by the pins, and when it passes through the pins, it come together again and flows at a relatively low shear rate.

By means of attaching pins, many effects can be obtained.

・The pin immediately after the feed zone increases the coefficient of friction between the cylinder liner and the cold rubber compound, changing the ratio of the axial and circumferential flow of the rubber. This increases the carrying capacity of the screw.

・At the center of the pin cylinder where the rubber compound is heated, the rubber flow is divided by the pins, and when it passes through the pins, it come together again and flows at a relatively low shear rate.

Product Features

- High extrusion capacity is possible because the transfer capacity of the screw is increased by the pin.

- Low temperature extrusion is possible because the shear rate is low.

- Low power consumption (energy saving)

- Good uniformity of extruded products (because the pin improves the rubber kneading effect)

- Easy to apply to a wide range of rubber

- No pulsation in extrusion

Standard specifications

- Screw diameter: φ60 ~ φ150mm

- ・L/D :12 ~ 16(20D for Vent type)

- Cylinder material: SACM645 Nitriding treatment

- Screw material:SACM645 Nitriding treatment

- Design pressure resistance: 35 MPa for regular use, MAX 50 MPa