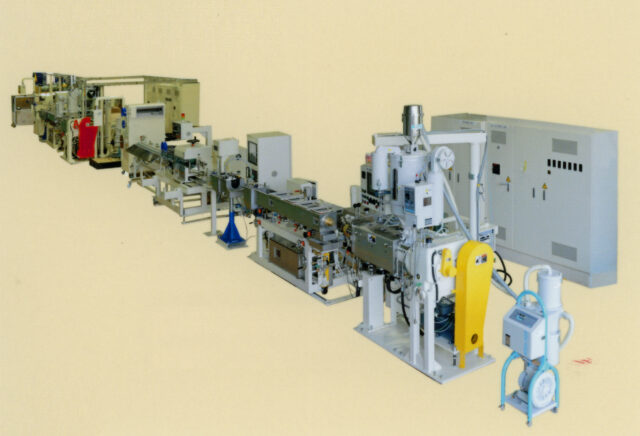

Fluororesin Tube Extrusion Line

Tubes made of fluororesin, which have features such as chemical resistance, non-adhesiveness, purity, and weather resistance, are used for transferring various liquids and gases such as high-purity liquids, fuels, paints, and chemicals used in semiconductor factories.

It is expected that needs will continue to grow in the fields of space equipment and nuclear power.

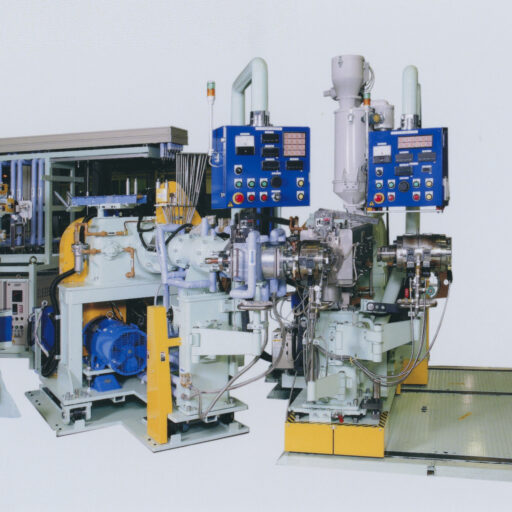

Mitsuba Manufacturing corporation's fluororesin tube extrusion line is designed and manufactured in-house not only as an extruder but also as a system from incidental equipment to control, making use of many years of experience and achievements to meet the above-mentioned various market requirements.

It is expected that needs will continue to grow in the fields of space equipment and nuclear power.

Mitsuba Manufacturing corporation's fluororesin tube extrusion line is designed and manufactured in-house not only as an extruder but also as a system from incidental equipment to control, making use of many years of experience and achievements to meet the above-mentioned various market requirements.

Product Features

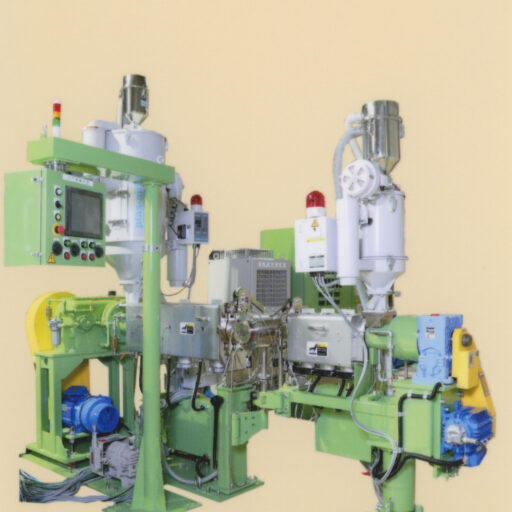

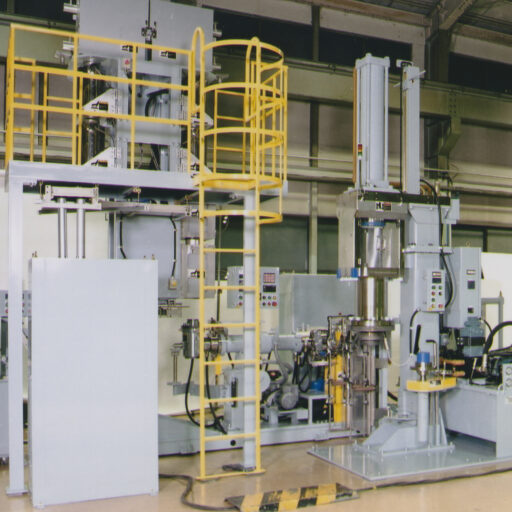

Fluororesin Extruder

- It is available each size from the minimum screw size φ14 mm to φ50 mm.。

※Please contact us separately for screw diameter more than φ50 mm. There is constraint such as materials. - Corrosion-resistant metal is naturally used where the resin comes into direct contact, such as the cylinder, screw, and head.

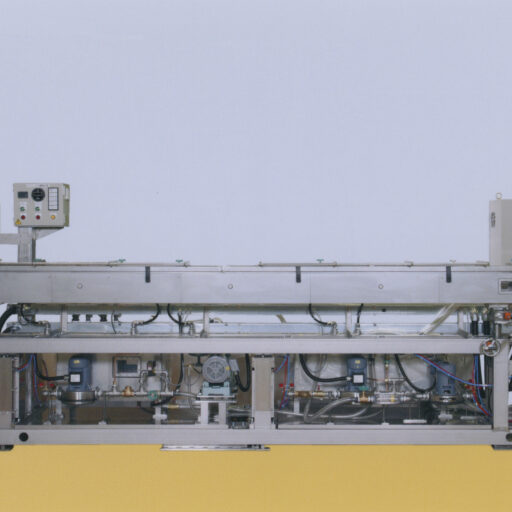

Sizing Water Tank

Our company’s unique vacuum pressure control suppresses fluctuations in vacuum pressure, and our sizing water tank enables tube forming for a long time with stable dimensions and roundness.

It’s possible to support both dry-sizing and wet-sizing.

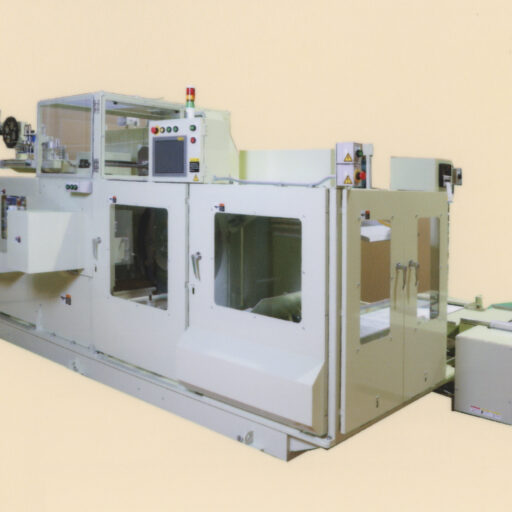

Winder

- We handle Horizontal cantilever shaft two head pick-up manual switching double barreled coiling machine.

This parasol bobbin is replaceable, so it can change sizes free to fit product wind specification. - This winder can use in concurrently with binding machine below.

Coiling machine

It is possible tying optimum clamp capacity prevent loosening band binding and crushing tubes. In addition, whole machine design is able to be space-saving because of tying machine can fit inside of bundling machine.