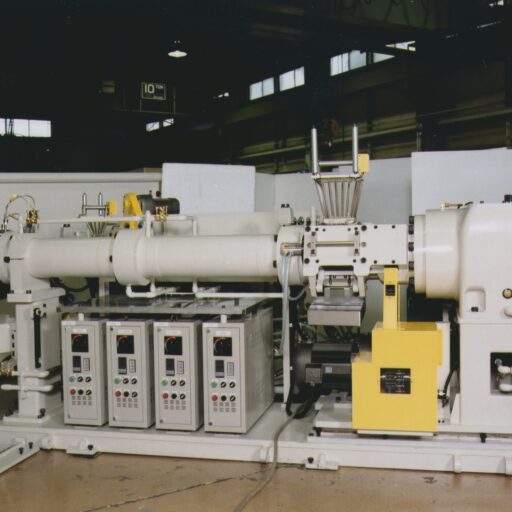

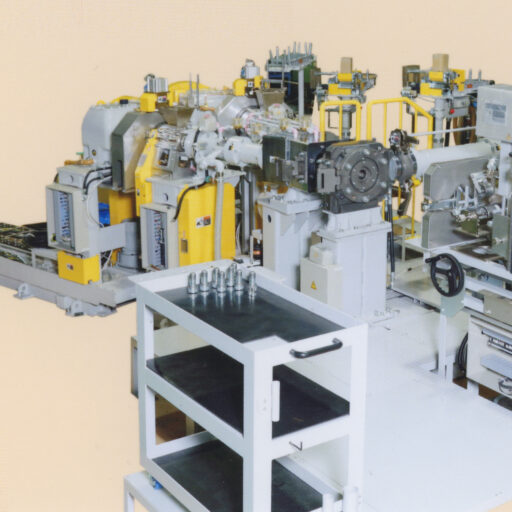

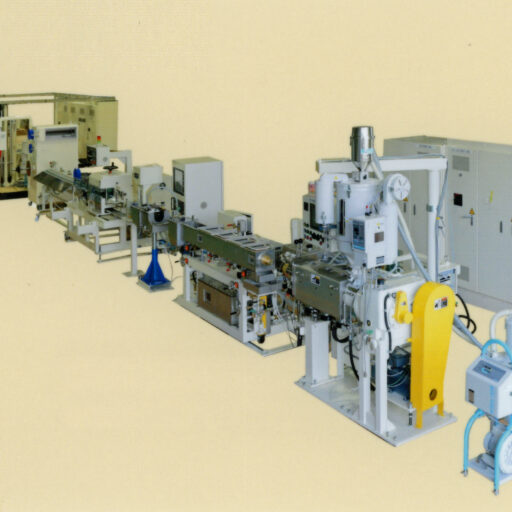

Rubber Plastic Composite Horse tube Line

This equipment is a line that produces hoses that combine synthetic rubber and fluororesin.

Taking advantage of our strength of being able to manufacture both rubber extruders and plastic extruders, we have various line-ups such as a line with a mandrel like this equipment and a line that extrudes rubber and plastic at the same time.

Our fluororesin extruder uses an extruder's material with excellent corrosion resistance.

Taking advantage of our strength of being able to manufacture both rubber extruders and plastic extruders, we have various line-ups such as a line with a mandrel like this equipment and a line that extrudes rubber and plastic at the same time.

Our fluororesin extruder uses an extruder's material with excellent corrosion resistance.

Product Features

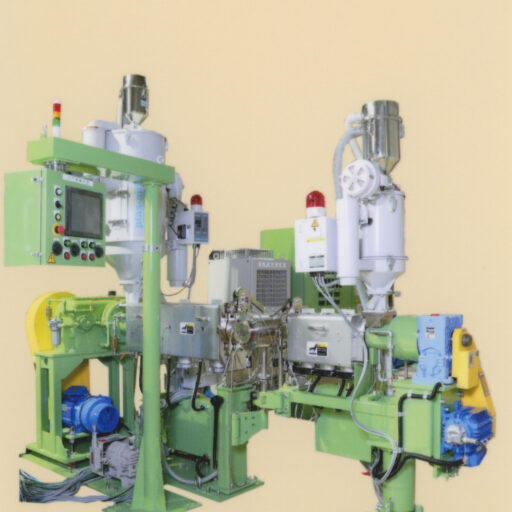

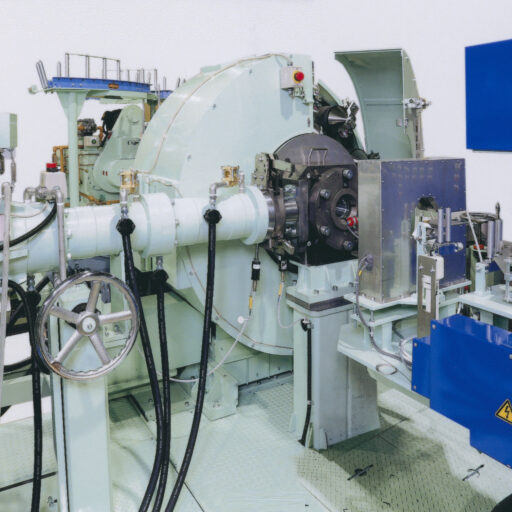

Back tension caterpillar pick up machine

- Back tension caterpillar pick-up machine with brake motor + powder clutch.

- Effective pressurized length, belt width, and belt material can be selected according to the pulling force and product.

- The caterpillar opening/closing mechanism can be manufactured by means of manual handle type, electric drive type or air cylinder type.

- Can be manufactured with vertical interlocking opening/closing type, upper opening/closing type, and lower opening/closing type depending on the application.

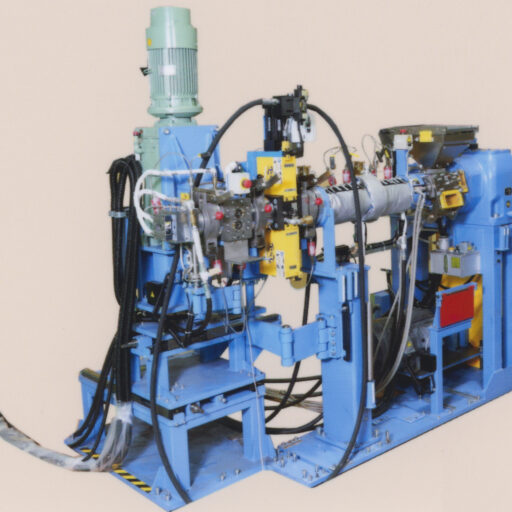

Rubber Extruder (Inner Layer, Outer Layer)

- Equipped with a vacuuming device on the head to improve adhesion to the mandrel

(Water-sealed vacuum pump: Capacity 2.2kW). With auxiliary supplied water tank, filter box and pressure gauge. - Crosshead is a centering type. Nipple with back and forth adjustment mechanism.

- A die heater is mounted to the tip of the head.

- A roller conveyor and a grid-type hopper with a rubber shortage detection mechanism are mounted to the rubber inlet.

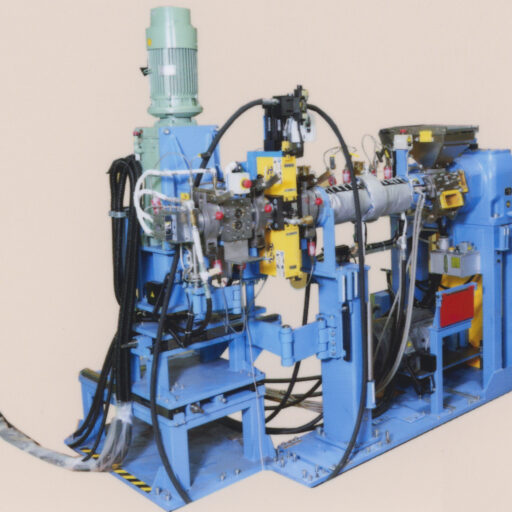

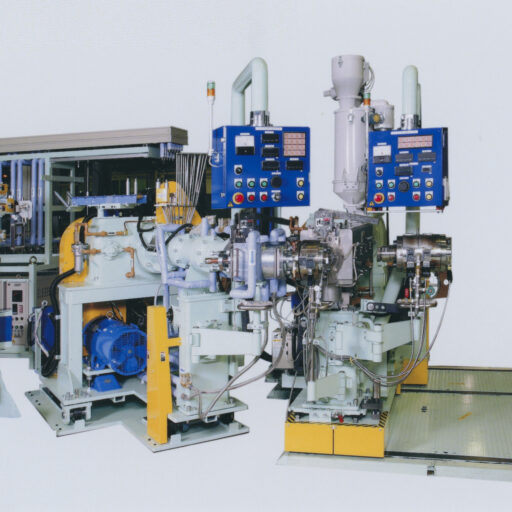

Fluororesin Extruder (Intermediate Layer)

- Equipped with a vacuuming device on the head to improve adhesion to the mandrel

(Water-sealed vacuum pump: Capacity 0.4kW). With auxiliary suppling water tank, filter box and pressure gauge. - Corrosion resistance measures are also taken for screws, cylinders, hopper openings and heads.

- The cylinder part is heated by an aluminum cast heater (3 zones)

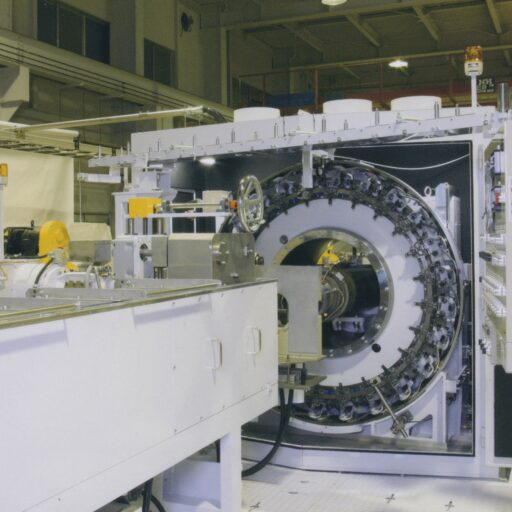

Winder

- The drum clamp is a pintle in/out type with air cylinders on both sides.

- The take-up motor is a servo motor that is mechanically linked to the Benly traverse.