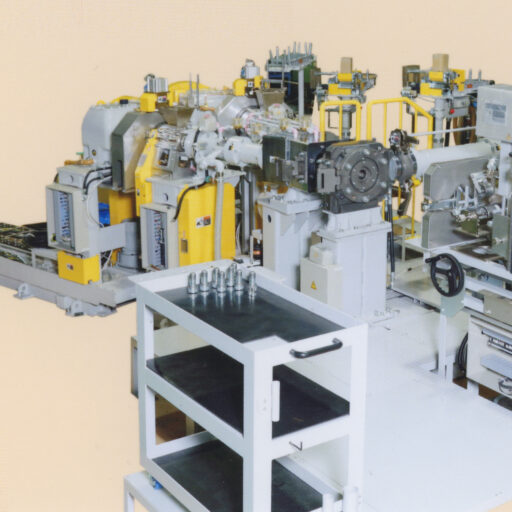

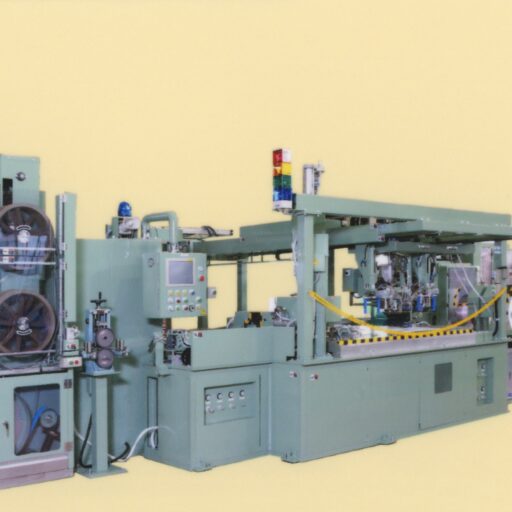

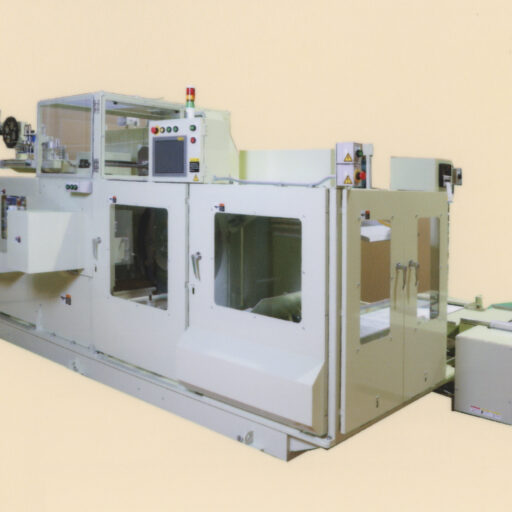

Automatic Tube Tying Machine

Product Features

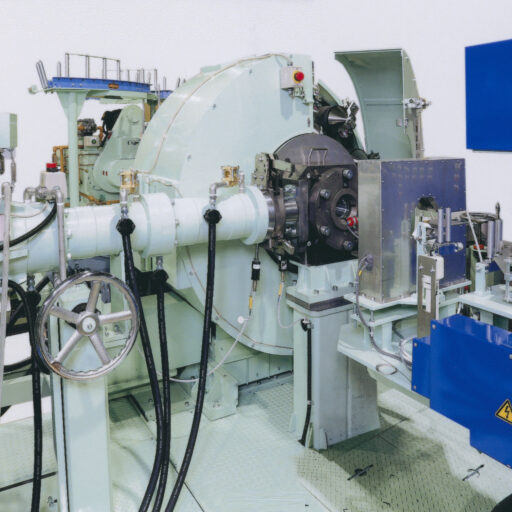

Self-Developed PP Band Tying Unit

For the tying device, we have adopted a proprietary PP band tying unit that we have made improvements based on many years of experience. Unlike a device that uses a commercially available tying machine for packaging, our tying machine has been developed for tubes, so the PP band is not loosened and tubes are tied with the optimum tightening force that does not damage the tube.

In addition, whole machine design is able to be space-saving because of tying machine can fit inside of bundling machine.

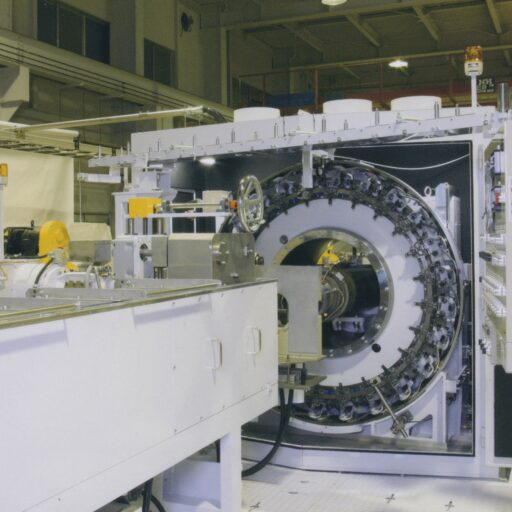

Continuous Operation Possible

Since it is a double-type tying machine that separates the bundling position and the tying/payout position, continuous production is possible without stopping production or slowing down.

Adjustable Bundle Size

Since the height and inner diameter of the bundle can be adjusted, the size can be changed in a short time without changing the reel even if there are several types of bundle sizes.

Abundant Model Configuration

We have models for small diameter air hoses with a tube outer diameter of φ3 mm to corrugated pipes with a diameter of up to φ31 mm, and they can bundle outer diameter of φ550 to φ950.

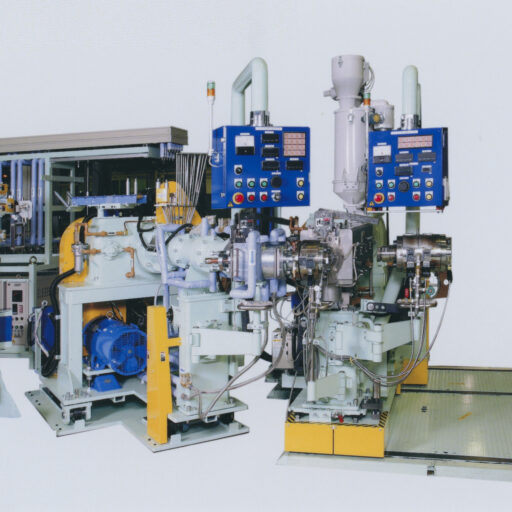

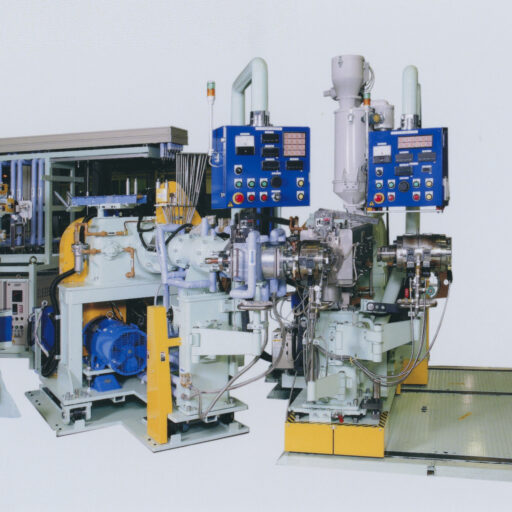

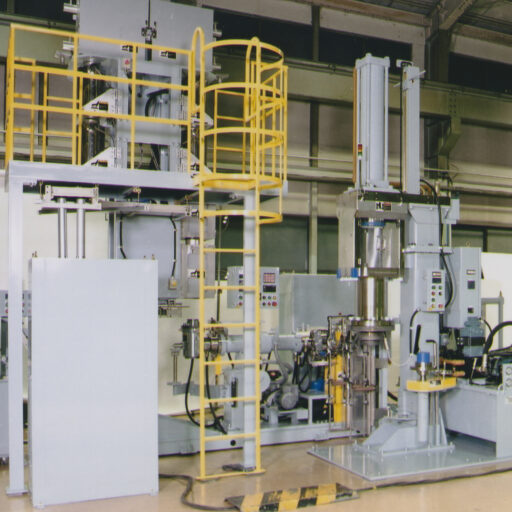

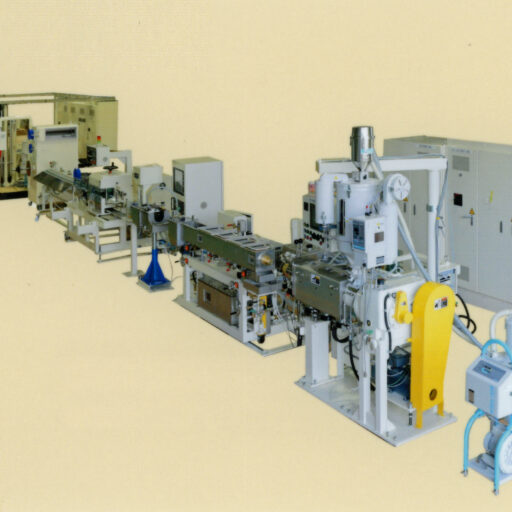

Extensive Up and Downstream Equipment

In addition to the tying machine, we offer an entire tube production line system including control from extruder to tying machine together with equipment like an accumulator that stores tubes under bundling time, a conveyor after payout and a palletizer.

Retention of Bundle Shape

By incorporating a plastic welder (purchased product) as an option, it is possible to prevent loosening PP band binding, collapsing stack of bundles and crushing tubes with air from the extruder by sealing the start end and the end