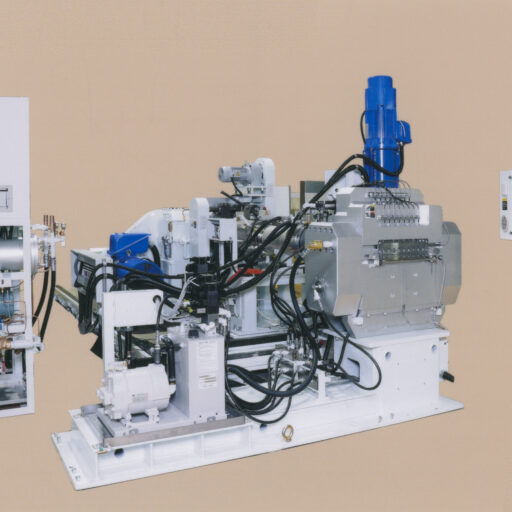

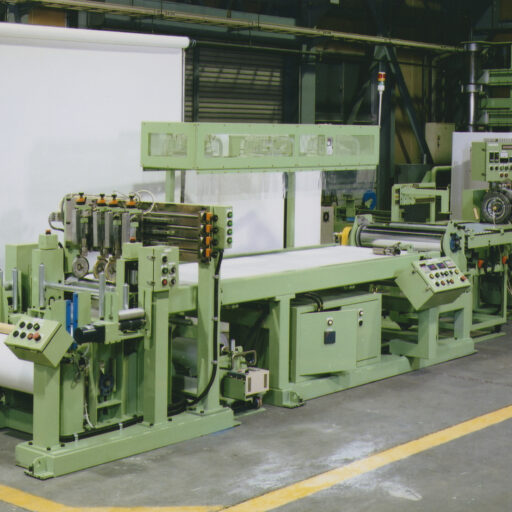

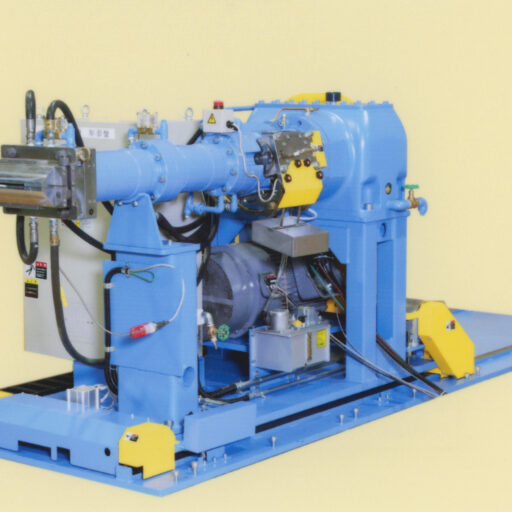

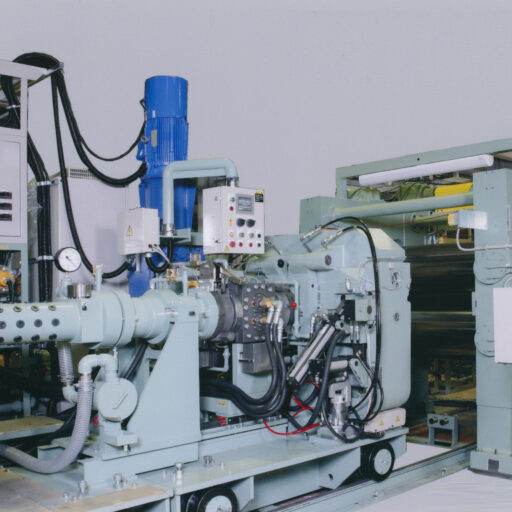

Calender systems

Calender technology from KraussMaffei Extrusion enables two-sided coating of textile cord or steel cord with rubber.

The rubberized textile cord replaces the hose and lends the tire its load-carrying capacity. The steel cord guarantees high driving stability and high running performance.

With the S model KraussMaffei Extrusion provides comprehensive solutions for coating.

The calender systems are customer-specifically equipped with 4 rolls. The modular structure and various additional features stand for the highest flexibility and productivity.

The rubberized textile cord replaces the hose and lends the tire its load-carrying capacity. The steel cord guarantees high driving stability and high running performance.

With the S model KraussMaffei Extrusion provides comprehensive solutions for coating.

The calender systems are customer-specifically equipped with 4 rolls. The modular structure and various additional features stand for the highest flexibility and productivity.

Product Features

- Rollers made of high-quality, premium materials with high molding precision, high surface quality and hardening •Various heating methods for rollers

- Various heating methods for rollers

- Extremely high concentricity due to special roll bearing system and circulating oil lubrication system of the roll bearing system

- Hydraulic roller nip adjustments or fast reaction time with the highest positioning accuracy, absolute repeatability and fast opening of the roller nip

- Hydraulic tilting and roll-bending equipment for compensation of roll deflection

- Calender drives for every intended application in absolute premium long-term quality

Ideal concepts for various products – reliable, flexible solutions For various applications, KraussMaffei Extrusion adapts the additional features upstream and downstream of the calender precisely to the requirements. This equipment, which is optimally adapted production process and ranges from various winders to non-contact thickness measurement systems to to the doubling and cutting equipment, enables short changeover times and ensures reliable production.