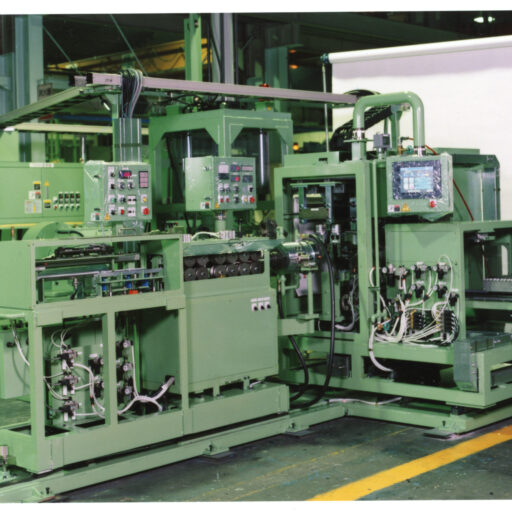

“COVERMATIC” series roll manufacturing device

Rolls made by the COVERMATIC series satisfy the highest quality demands of contemporary printing and coating applications.

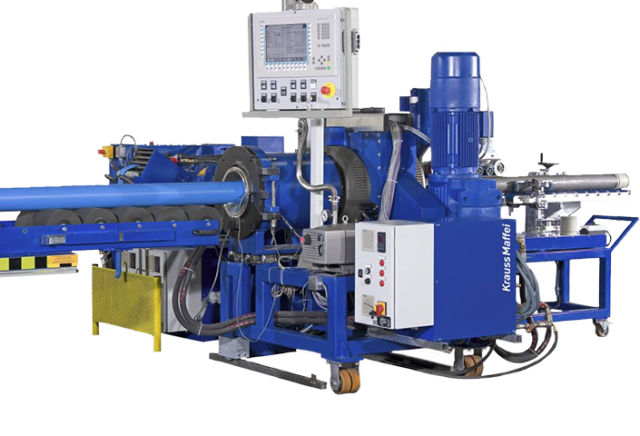

Capable of processing rubber compounds with Mooney viscosities ranging 20 to 110. Capable of covering core diameters of 5 to 310 mm (Diameter), with rubber compounds in thicknesses between 3 and 40mm, regardless of the core's length, and without leaving any overlaps or seam lines.

Capable of processing rubber compounds with Mooney viscosities ranging 20 to 110. Capable of covering core diameters of 5 to 310 mm (Diameter), with rubber compounds in thicknesses between 3 and 40mm, regardless of the core's length, and without leaving any overlaps or seam lines.

Product Features

- Excellent quality of covering

- High precision covering needs minimum grinding allowance

- Degassing ensures no air inclusions or inconsistencies

- Little or no post-extrusion work

- Simple and rapid changes of size or compound type

- Easy to operate via central panel

- Low manning requirements

- State-of-the-art controls with PLC and operator panel

- Storage possibility for production and process data (recipes)

- Direct or graphic display of all relevant data in digital or graphic