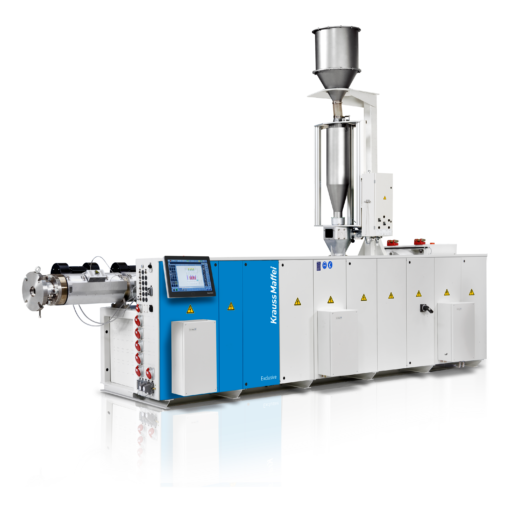

Edelweiss Compounding

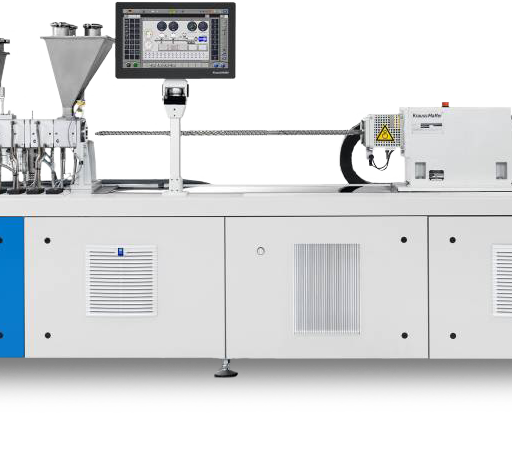

KraussMaffei's extrusion systems for recycling processes meet the highest demands regarding quality, efficiency and durability. The high-performance single- and twin-screw extruders can be employed both as an individual machine or in combination with a cascade process for clean regrind in-house plastic, post- consumer or post-industrial waste.

KraussMaffei has linked together diverse tasks, such as material compaction, degassing, filtering and compounding to automated systems. The system provides a tailored solution for any plastics recycling and compounding task.

Sorted / pre-washed post-industrial waste as well as post-consumer waste, reusing in low and high bulk density materials with even handling humidity content up to 10%, co-rotated twin extruder is a real novelty in recycling step or compounding step.

KraussMaffei has linked together diverse tasks, such as material compaction, degassing, filtering and compounding to automated systems. The system provides a tailored solution for any plastics recycling and compounding task.

Sorted / pre-washed post-industrial waste as well as post-consumer waste, reusing in low and high bulk density materials with even handling humidity content up to 10%, co-rotated twin extruder is a real novelty in recycling step or compounding step.

Product Features

- Co-rotated twin screw extruder has unlimited in throughput capacity 4.6 or even 8 tons/hours

- Good mixing machine in terms of dispersive and distributive mixing balanced and homogenized.

- High degassing efficiency due to the constant surface renewal of melt with large degassing opening (Taking out volatizes and odor and smell in final products.)

Advantages of Edelweiss Compounding with Cascade Extrusion Process

- Complete recycling and compounding in one step

- Maximum reduction of thermal stress

- Energy and time saving production

- Added value to the supply-chain

- Large range of applications