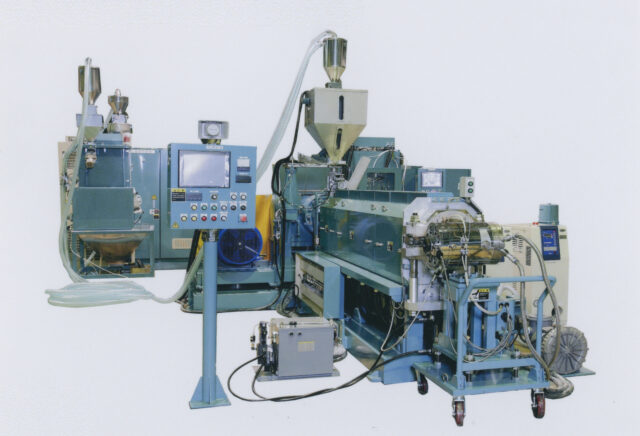

Extruder for One-Step Silane Cross Linking

It is already well known that the weakness can be improved by increasing the intermolecular bond by a method called cross-linking. Many of the several cross-linking methods have the disadvantage that they require high equipment costs because the lines are dedicated in special.

The one-step silane cross-linking method in which polyethylene and silane cocktail (silane coupling agent), which are the base polymers, are supplied together in the hopper of the extruder to cause a graft reaction in the cylinder,

can be changed only by the extruder part without changing the other devices. Since the front and rear devices can use the existing line, it is a manufacturing method that can be expected to significantly improve running costs and workability with a relatively low investment expense amount.

At MITSUBA, we have our own in-house developed silane injection as well as a variety of one-step silane cross-linking extruders in each size according to customer specifications.

Product Features

1.Mitsuba Original Development of Silane Injection

The silane injection developed by our company can be linearly supplied to the extruder even if the number of rotations is increased, without any variation in the discharge of the silane cocktail material.

2.Cylinder and Screw Shape

Cylinder: A grooved liner is used under the hopper to stably push the resin pellets with the silane cocktail attached to the tip of the cylinder without slipping.

In addition, the groove shape is such that the silane cocktail does not easily remain in the groove.

Screw: A special shape is used to evenly mix the silane cocktail and resin pellets.

3.Temperature Control

Since stable temperature control is required for a uniform cross-linking reaction, the heating and cooling method for each zone is selected by using the hot oil circulation type or the electric heater + blower type.

4.Maintainability

We design and manufacture all extruders, silane injection and control.

Except for special parts, we basically use products from Japanese manufacturers, so we can get consumables as soon as possible.

In addition, PLC is also designed by Mitsuba using a familiar domestic manufacturer, and it is possible for the customer to change it after delivery.

5.Offer on Turn-key line

In addition to extruders and silane injection, we also design and manufacture in-house the ancillary equipment such as hall-off machines and winding machines. Please contact us as we will propose and provide one set of production line.