Head for Cross Sectional Shape in Weather Strip 4 Layers

By the cross-sectional shape optimized for the door structure of an automobile, we realize a sense of luxury when you close the door in high waterproof and sound insulation as well as decorative tailored interior. The customized requirements get multilayered profile more progressed.

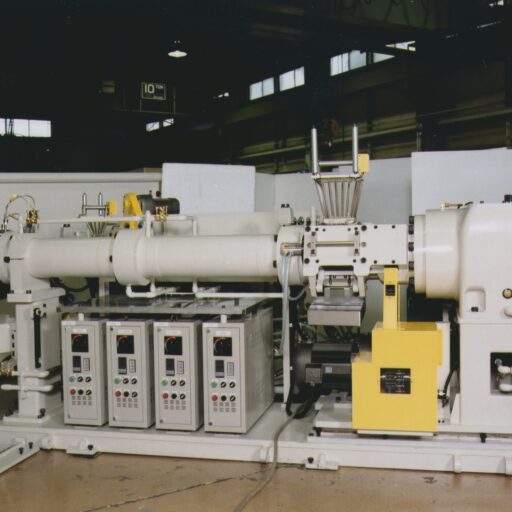

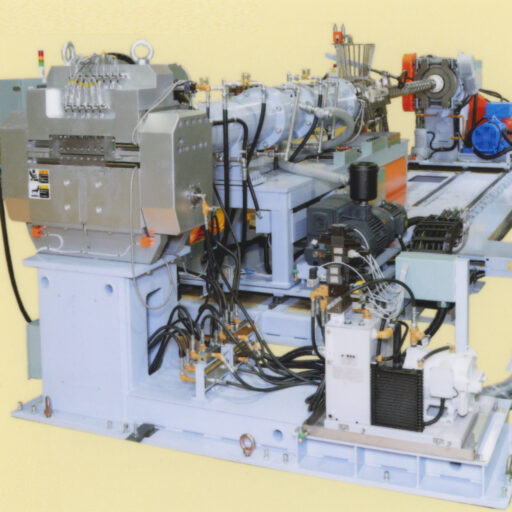

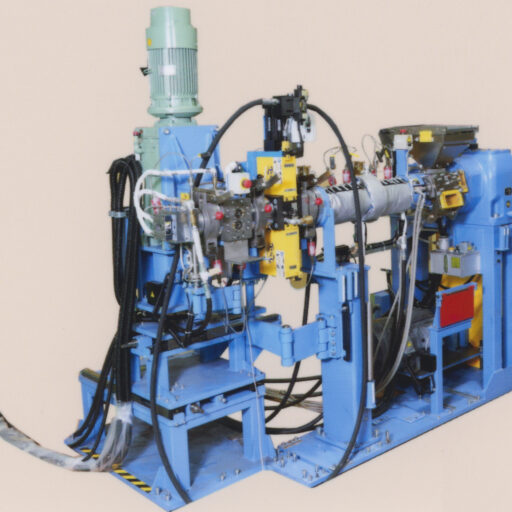

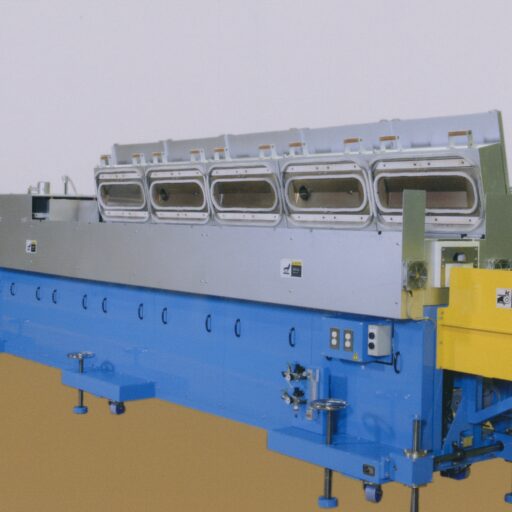

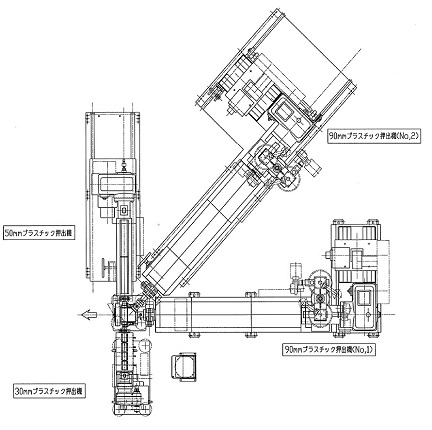

On the one hand, extruder used for each layer depending on the production speed is used 40mm ~ 120mm. It is required of shorter residence time of rubber in the head within the positional constraints and the flow path design that does not put back pressure as much as possible.

Workability of inserting the metal core material in the head is also considered since it is to ensure the mounting of weather strip to body firmly by putting the framework of metal core material depending on the parts.

On the one hand, extruder used for each layer depending on the production speed is used 40mm ~ 120mm. It is required of shorter residence time of rubber in the head within the positional constraints and the flow path design that does not put back pressure as much as possible.

Workability of inserting the metal core material in the head is also considered since it is to ensure the mounting of weather strip to body firmly by putting the framework of metal core material depending on the parts.