High Performance EVA Sheet Extrusion

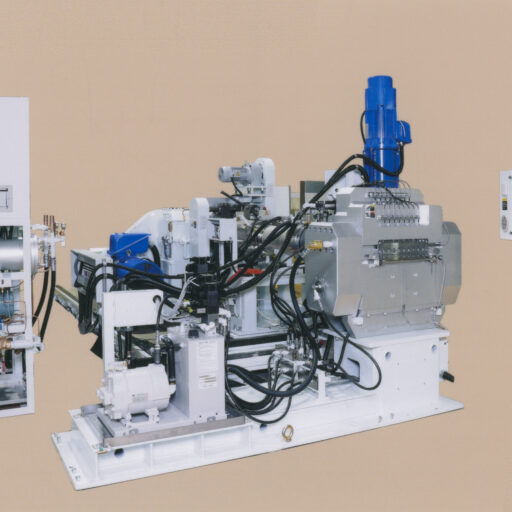

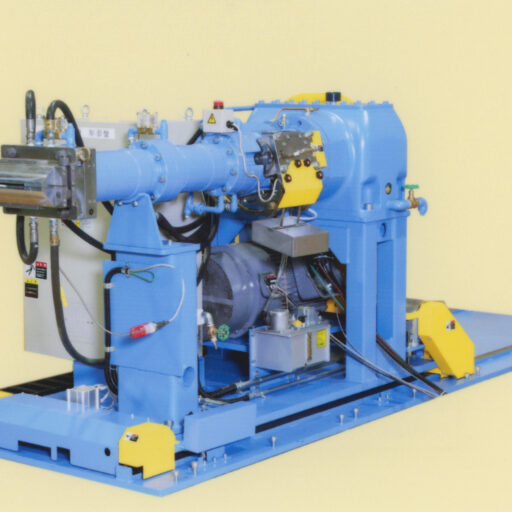

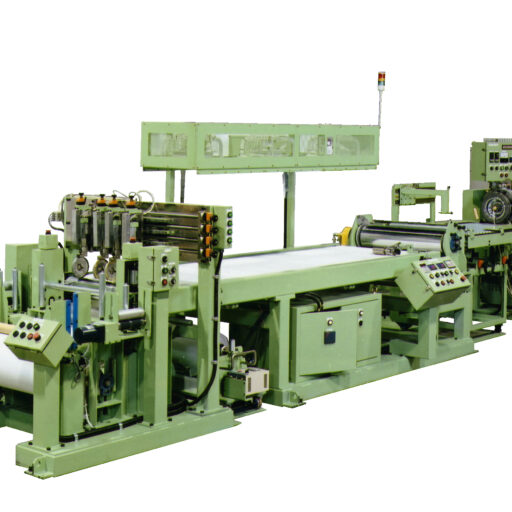

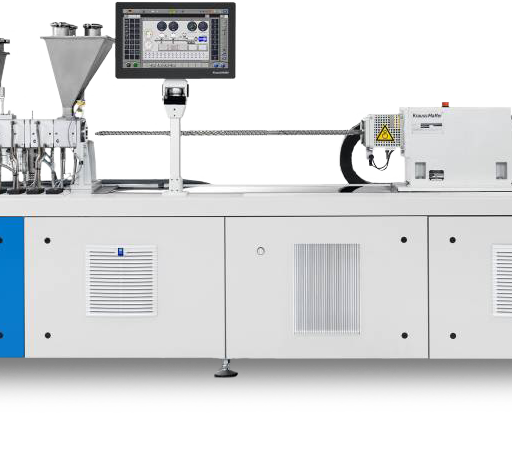

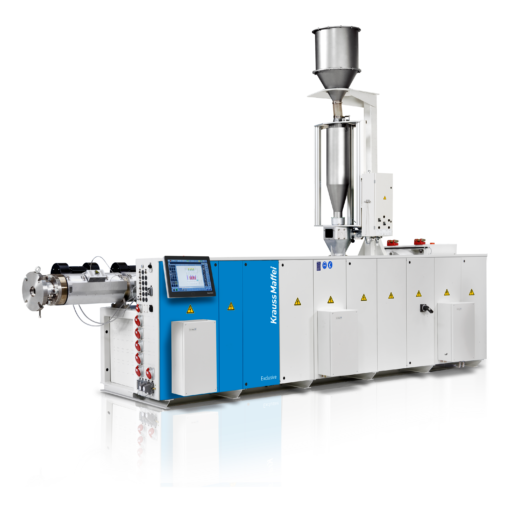

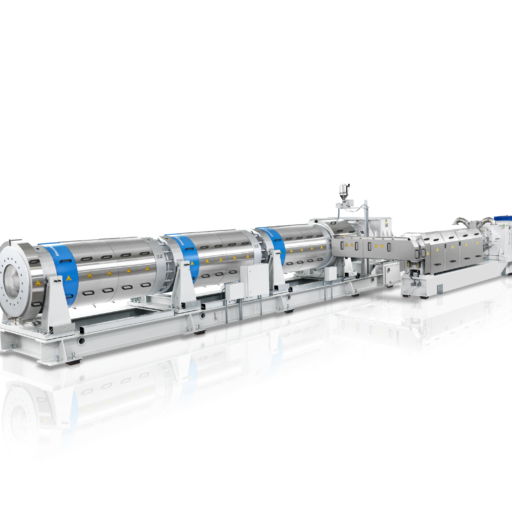

Twin screw extruder: ZE / UT series are equipped with a slot die with automatic die gap adjustment function, gear pump and evacuation. They are designed for EVA sheet production, achieving high quality, versatility and low production cost.

Product Features

- It is possible to centrally homogenize materials from special customer-specified materials and surface finishes to the optimum screw shape.

- 100% recycled flakes can be processed, and it is applied to the production of high quality EVA sheets. (It does not affect the quality of the final product at all.)

- Twin screw extruder that supports modularization

<Processing task test with KME equipment>

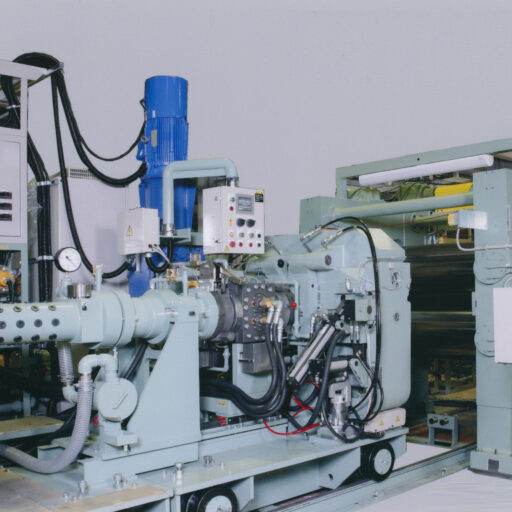

- You can perform your individual tests using KME Hanover’s state-of-the-art equipment of technical center.

- (eg, suitable vulcanization equipment, planet calendar, on-line material formulation ZE60UTX: twin-screw extruder).

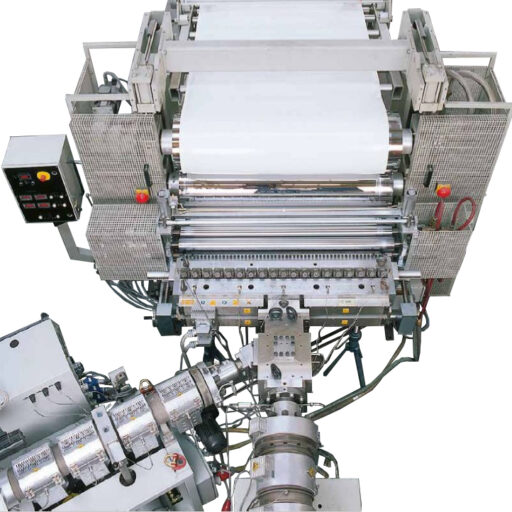

- With the assistance of KME’s skilled technicians, using your materials under actual production conditions, KME can produce up to 1,100 mm sheet width.

- KME designs your company’s new production line and assists in optimization processing before launch.