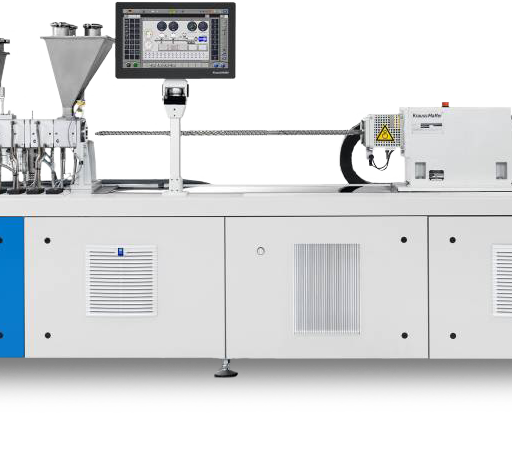

KMD32 type counter-rotating twin-screw extruder

Extruder for U-PVC extrusions for window profiles, etc..

The L/D ratio of conventional machines was increased from 26 to 32, to increase the specific output.

The 32D twin-screw extruder is suitable for the production of window frame profiles, cable ducts, foam profiles, and the production of co-extrusions.

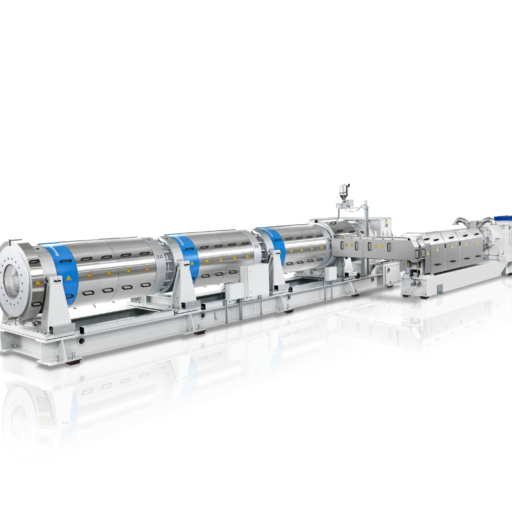

The L/D ratio of conventional machines was increased from 26 to 32, to increase the specific output.

The 32D twin-screw extruder is suitable for the production of window frame profiles, cable ducts, foam profiles, and the production of co-extrusions.

Product Features

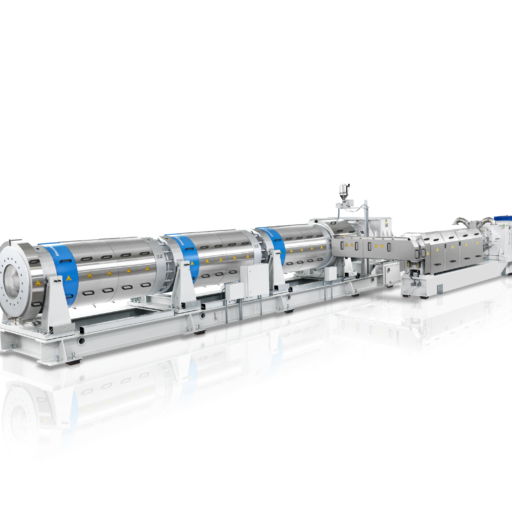

The L/D ratio of conventional machines was increased from 26 to 32, to increase the specific output.

While the energy input is increased, the shear energy is reduced, improving the overall energy balance, leading to greater flexibility with respect to various additives (such as stabilizers).

Further, the newly developed screw design enables optimal and automatic control of the internal temperature of the screw, improving compound homogeneity and reducing pressure fluctuations, resulting in outstanding improvements to product quality.

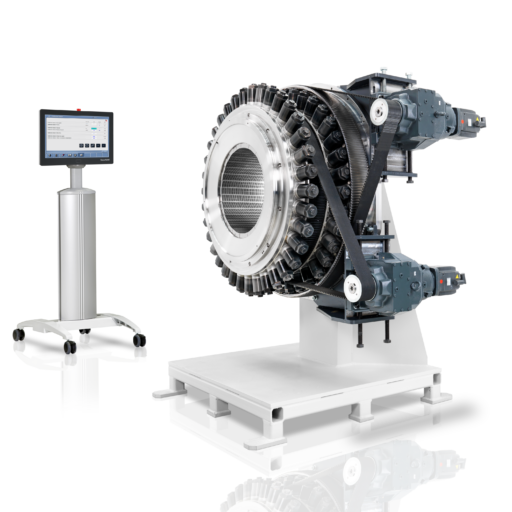

A strong gearbox that can withstand high screw torques is adopted. The compact and rugged gearbox is of a low vibration type that is designed to withstand even the backpressure of the screw.