LCM – Salt bath plants for the curing of rubber profiles

This means that the treated parts are rinsed thoroughly, using a minimum of fresh water, in a cascade washing system, and that the relatively small amount of rinsing water can be processed very economically. The recycled salts can be used again. Should a recycling not be possible, the salts concerned must be disposed of in accordance with the local regulations. Durferrit GmbH will, of course, be glad to help customers find suitable solutions to their problems.

Product Features

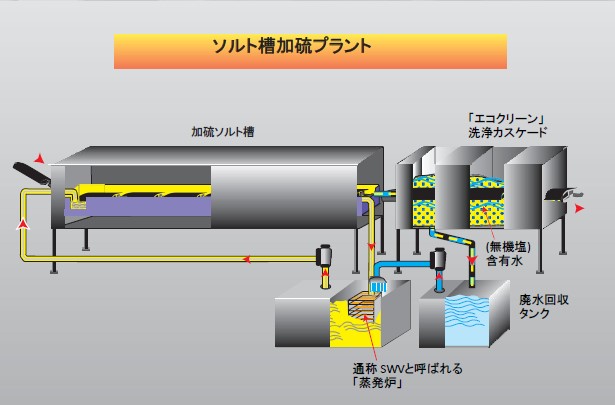

In a separate electrically-heated or gas-fired salt bath furnace, the salt melt is warmed up to curing temperature, which is between 200° C and 280° C. By means of an electromotive salt bath pump especially developed for this purpose, the salt is pumped into the curing bath through a pipeline or also by a sprinkler unit.

At the end of the curing salt bath pot, the molten salt runs back into the supply salt bath via an outlet. In this central supply salt bath there is a desludging area with a strainer screen through which the salt flows back into the pot. At the same time, floating particles, sludge and carbonates are separated from the curing salt bath, and can be removed easily.

The curing salt carried out with the rubber profiles is concentrated in the rinsing cascade, solid particles are filtered out, and the reaction foam is (for example stearites) automatically removed.

By means of an automatically controlled pump, the concentrated salt solution is pumped out of the waste water collecting tank and sprayed onto the surface of the separate supply and regeneration salt bath. The rinsing water evaporates, and the reclaimed salt is again in the supply cycle.

<Advantages of the system compared with conventional curing salt baths>

- The continuous filtering and cleaning of the curing salt bath ensures high quality results.

- Almost all the salt dragged out of the bath is regained and reused.

- Feeding the curing plant with molten salt ensures a uniform temperature. Fluctuations in temperature due to filling of the curing salt bath with solid fresh salt do not occur.

- Due to the continuous inlet and outlet of molten salt, the level of the curing salt bath remains constant, so that the pressure on the rubber profiles is always the same.

- The supply and regeneration salt bath can be gas-fired, and is therefore particularly economical to operate.

- Continuous desludging ensures there is no fire-risk due to rubber particles floating in the curing plant.