“MULTIPLEX” system (multilayer extruders) for tire parts

Using four extruders or more, different types of rubber compounds can be precisely extruded from the head, free of any intake of air.

Complicated cross sections, such as designs incorporating chimneys, can be extruded smoothly.

Extruders that output up to six layers (Hexaplex) have been delivered.

Product Features

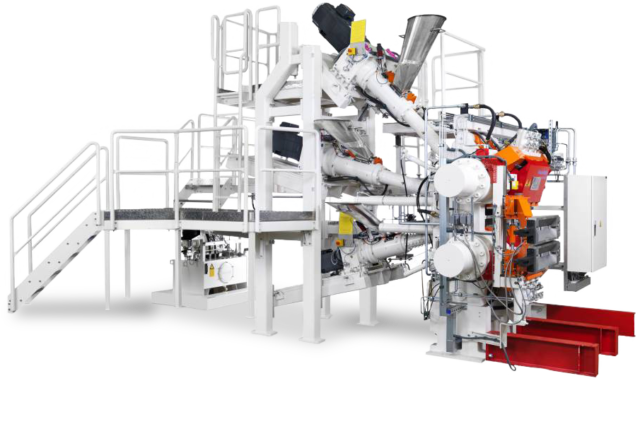

KraussMaffei extrusion lines are conceived for high product quality and maximum output

and are equipped with extruders of different types (GE-SC or GE-KS) and sizes.

The modular design makes for rapid reconfiguration to suit the mode of operation – Mono, Duplex, Triplex, Quadroplex or Quintoplex.

KraussMaffei Multiplex extrusion sets are designed in a piggy-back arrangement to achieve the highest product quality through symmetrical material flow in the head.

In addition, the compact design makes for real space savings. A further feature to satisfy the quality requirements is the special design of the flow channels in the extrusion head. These ensure a very gentle, even material transfer from the round section at the extruder outlet to the rectangular flat form of the profile. In addition, the changes in direction of the material flow in the flow channel are kept to a minimum.

All stages of the process are controlled by a monitoring system, thus ensuring operational security.

Throughput rates of up to 10,000 kg/h or about 30,000 passenger car treads per day are achieved with these modern extrusion lines.