PE pipe line

We create unique designs to meet customer needs, and in particular, our quick switch system (variable pipe diameter) and internal pipe cooling (IPC) system have achieved excellent productivity and energy efficiency.

We also handle large pipe production lines suitable for long-distance transportation of large quantities of drinking water, wastewater, and sewage.

Product Features

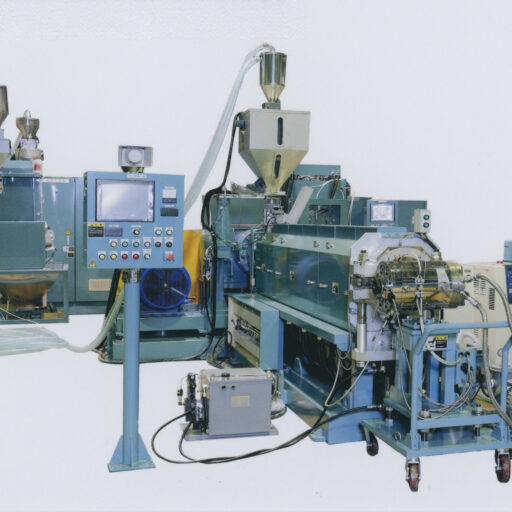

Plastic Extruder

We Mitsuba have the screw diameters from Φ14 mm to Φ150 mm extruders. We will provide the optimum size depending on the resin material and the throughput amount of extrusion.

※Please contact us for screw diameters over Φ150 mm extruders as it can be handled separately.

High Discharge Type Resin Extruder

The special shape of the screw and cylinder makes it possible to extrude the same throughput as the conventional extruder even in the high rotation range which was suppressing the heat generation of the resin with the rotation range decreased due to the limitation of the resin temperature. It can be handled with a smaller extruder of 1 to 2 sizes down.

Extruder for One-Step Silane Cross Linking

- The silane injection developed by our company can be linearly supplied to the extruder even if the number of rotations is increased, without any variation in the discharge of the silane cocktail material.

- Cylinder: A grooved liner is used under the hopper to stably push the resin pellets with the silane cocktail attached to the tip of the cylinder without slipping.

In addition, the groove shape is such that the silane cocktail does not easily remain in the groove.

Screw: A special shape is used to evenly mix the silane cocktail and resin pellets. - Since stable temperature control is required for a uniform cross-linking reaction, the heating and cooling method for each zone is selected by using the hot oil circulation type or the electric heater + blower type.

KME pipe manufacturing line

Since we are affiliated with KraussMaffei, we also handle their equipment. KraussMaffei product portfolio covers single-screw extruders, counterrotating and corotating twin-screw extruders with corresponding pipe heads and downstream components through to fully automated pipe lines, processing