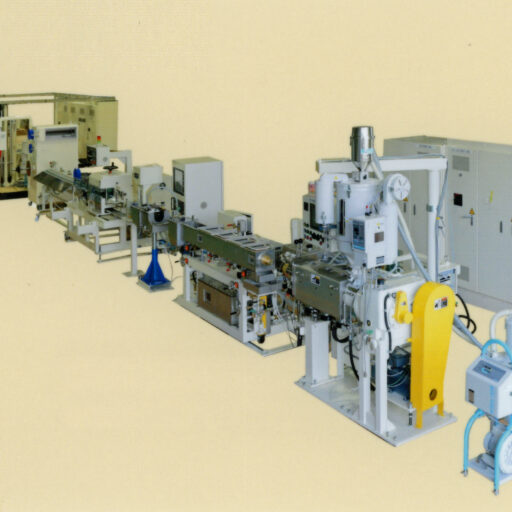

PFA Thin Tube Line

Product Features

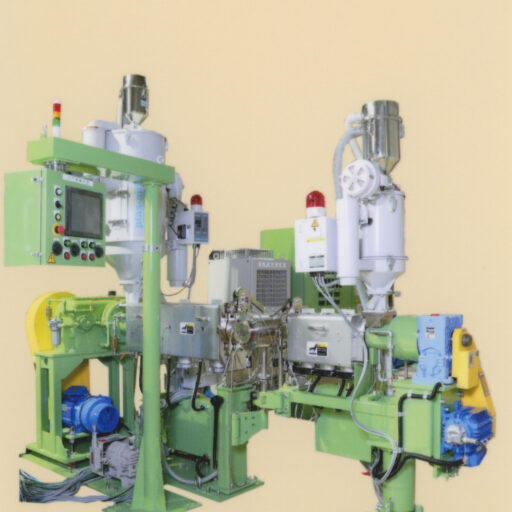

Fluororesin Extruder

Extruders using corrosion-resistant metal with fluorine gas are available in various sizes from screw diameter φ14mm to φ50mm. You can select an extruder of a size according to the tube diameter and wall thickness.

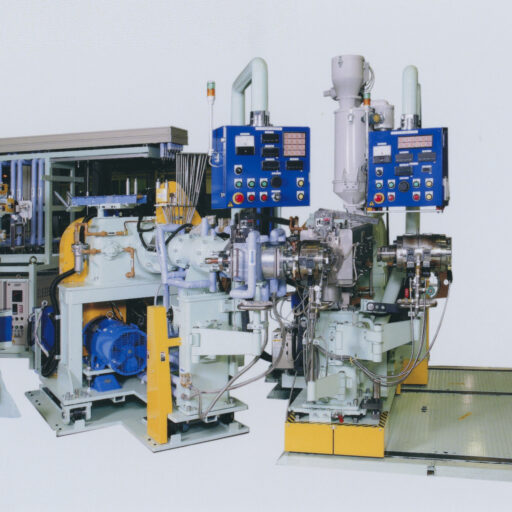

Inner Sizing Method By Downward Extrusion

By adopting the downward inner sizing method, the resin extruded into the protruding part of the head tip called the sizing die comes into uniform contact and is cooled to be able to form tubes without variation of the wall thickness (film thickness) in the circumferential direction.

The crosshead also has a special spiral-shaped several-divided flow path design for the purpose of extruding tubes of uniform wall thickness with inconspicuous weld lines.

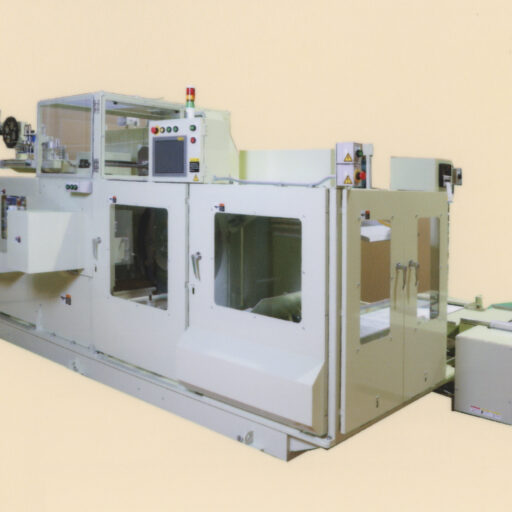

Space-saving Design

Since the extruder to the winder are mounted on a common base (* may be a split base for transportation and carry-in convenience), installation and centering are easy, and the installation space is as Mitsuba standard machine (drawing below) a space-saving design with a line direction of 6.5m and a depth of 2m. In addition, since there is one power supply port and one water source inlet on the primary side, installation work is easy.