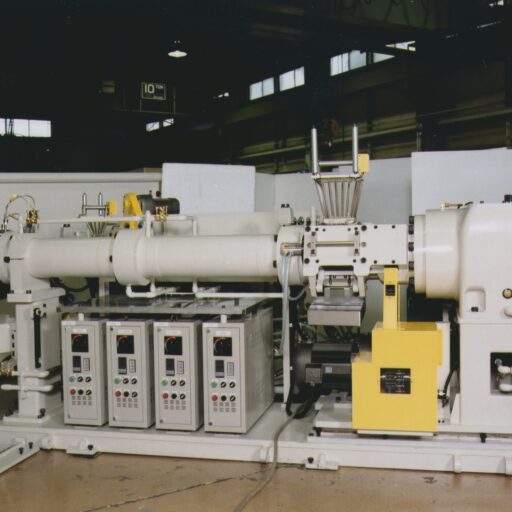

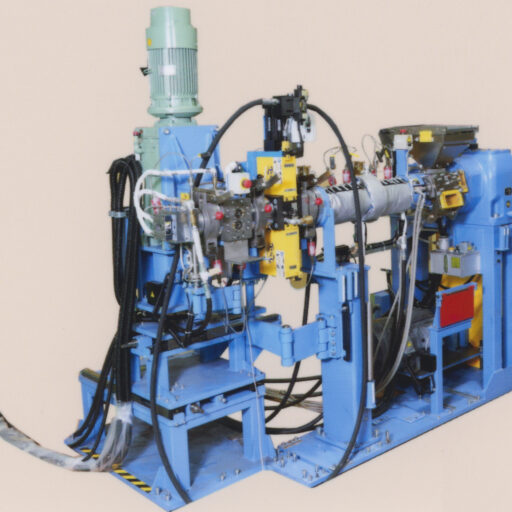

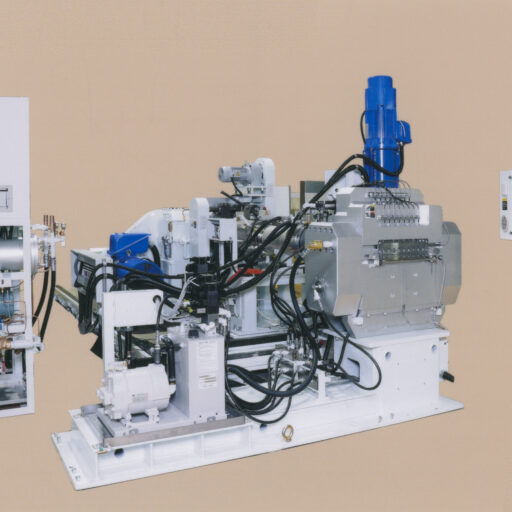

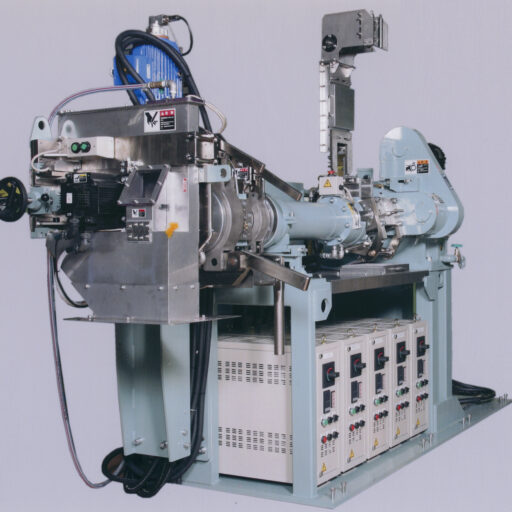

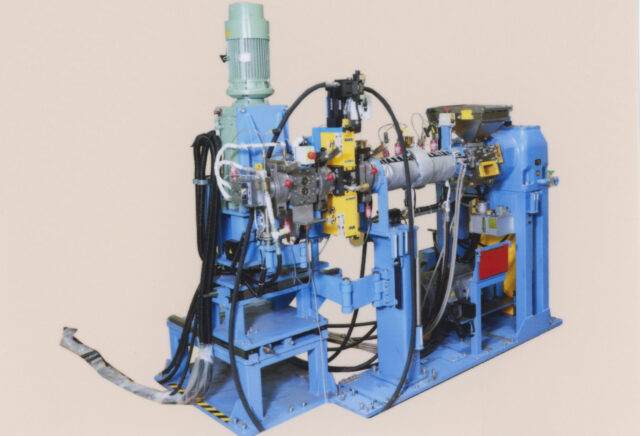

Rubber Extruder with Gear Pump

Since the rubber extruder performs the functions of transporting, heating, kneading, and weighing with screws, it was inevitable that the rubber temperature would rise due to pressure rising in the measuring section.

A rubber extruder with a gear pump is an optimal combination that takes advantage of both the weighing function of a gear pump that does not require pressure rising and the extruder's features of transfer, heat heating, and kneading.

Taking advantage of this feature, it is effective in various fields such as supply to calender, heating, profile extrusion, tube / hose extrusion, pre-forming where demands for quality improvement such as appearance, accuracy, and foreign matter removal are becoming stricter.

Product Features

1. Stable extrusion

Since the valleys of the gear with small volumes are filled with rubber and extrude them, it is possible to extrude with high precision with less variation in the extrusion amount per rotation than when extruding with the extruder alone.

It is effective for manufacturing thin-walled and small-diameter products with strict dimensional accuracy and for preformers before the press process that requires suppress weight variation.

In addition, there is also a high-precision type with increased number of gears to reduce the volume per valley which improves extrusion accuracy further and suppresses pulsation, so you can select according to the application.

2. Low temperature, High extrusion volume

By combining a gear pump and an extruder, the screw of the extruder is intended for transfer and kneading to the gear pump, eliminating pressure rise in the metering section. This suppresses the heat generation of the rubber material due to the pressure on the extruder side,

and can extrude at a lower temperature than using the extruder alone.

Since the rubber temperature can be extruded low, the screw rotation range of the extruder is widened and the discharge rate is increased.

In addition, even if a fine mesh is used, the extrusion rate does not decrease, so when used as a strainer, it removes finer foreign matter and has the effect of improving quality.

3. Yield improvement

By combining with a gear pump, the discharge is stabilized in a shorter time than when the extruder is used alone, so material loss can be reduced. In addition, the remaining rubber in the cylinder can also be used as a product because the discharge amount can be stably extruded even after the material supply into the extruder has been stopped at the end of production.

4. Combination with vent type rubber extrude

With the vent type extruder alone, there were problems of venting up and starvation feed at the dam part due to the extrusion shape and rubber hardness. But by combining the gear pump and the vent type extruder, the extruder can keep the inlet pressure constant. Since the screw rotation is controlled,

it is possible to produce with one screw without worrying about the problems caused by the extrusion shape or the extrusion pressure due to the rubber material.