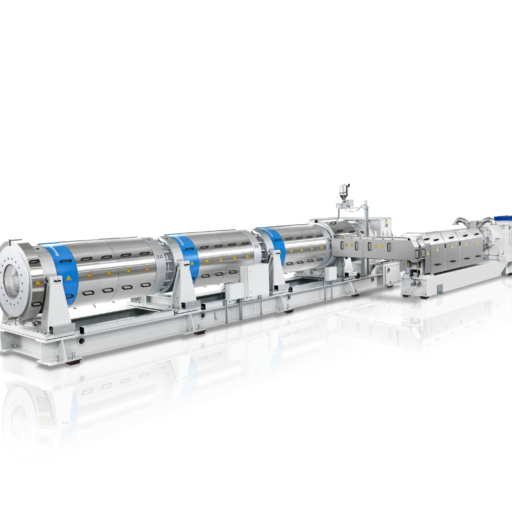

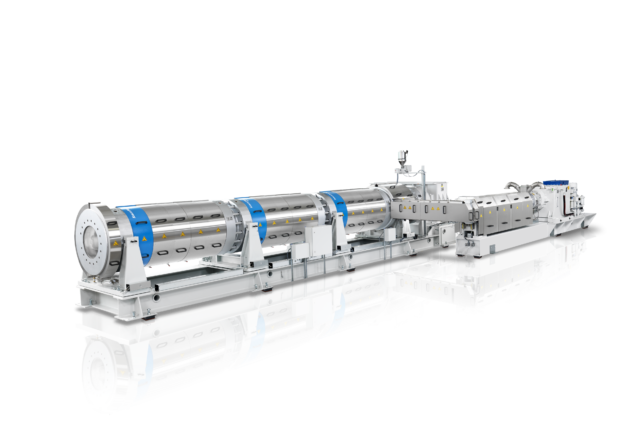

Shaumtandex ZE40/KE90

The feature is that it is composed of two stages, a plasticization/gas injection stage and a cooling stage.

Product Features

- The extruder is equipped with a patented ASD type special seal, which can effectively cope with stable operating conditions for liquid or gas foaming agents and sensitive foaming processes with high pressure line.

- Adopting environmentally friendly physical foaming, it can handle from PS, PE and PP to heat-resistant polymers of PET, PEI and PES.

- The first stage uses co-rotating twin screw extruder that rotates in the same direction so that the gas is evenly dispersed in the melted elastomer. The second stage is cooled and conveyed by a single-screw extruder.

- This is used for manufacturing for building material of heat insulating boards, foam beads, Soundproof sheets, packaging materials, food trays, etc.