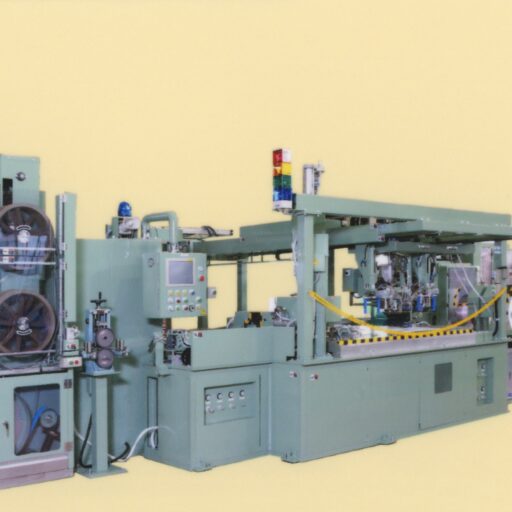

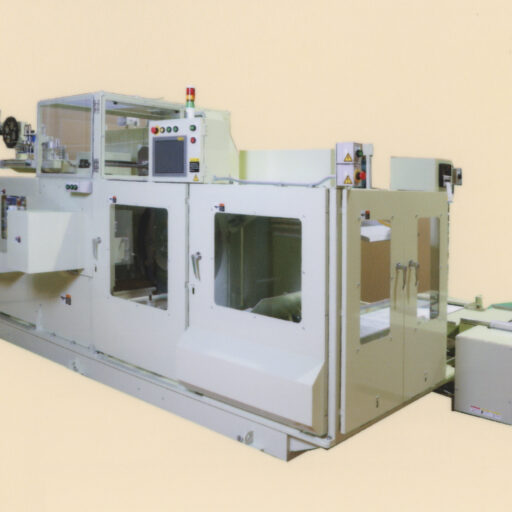

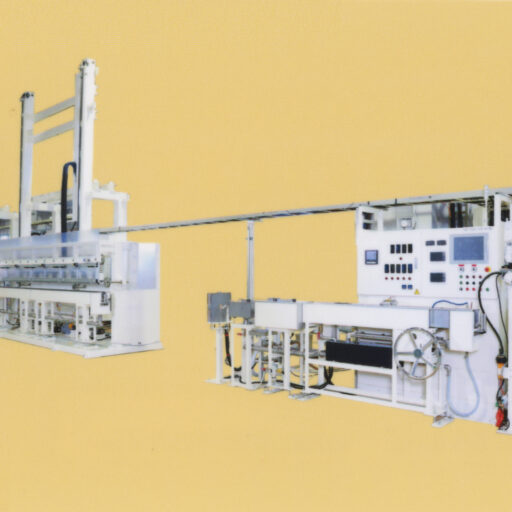

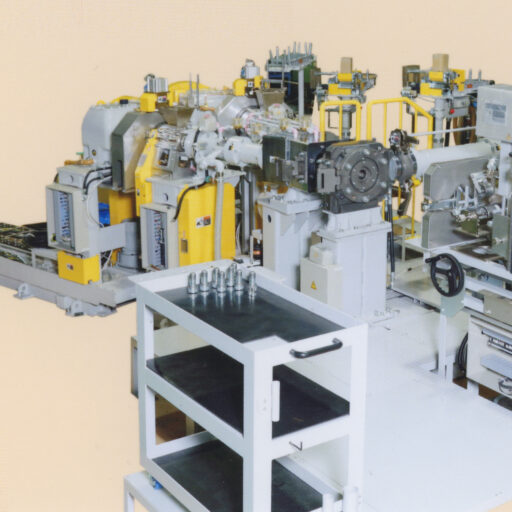

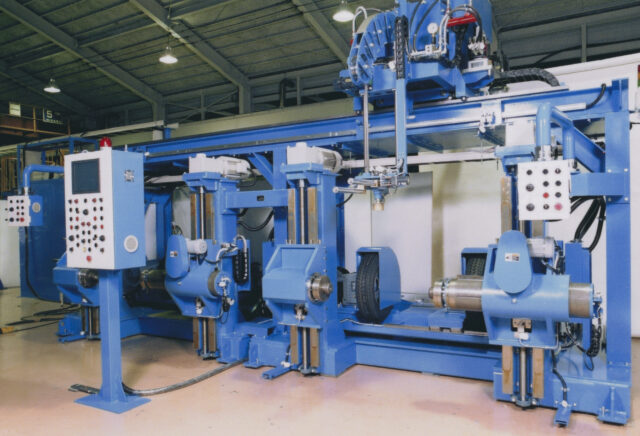

Tire Drive Pay-off/Take-up Machines

The number of repeaters is increasing, as it has been highly evaluated by users because it has improved work efficiency.

Product Features

1.Shorter Setup time

Lathe dog is not required because tire drives drum flange directly.

The setup time can be shortened by eliminating the work of replacing lathe dogs and adjusting position depending on drum type and sizes.

2.Maintainability

Unlike a link type drive system that uses a sprocket, it is easy to maintain because it is a simple drive system in which tire is directly attached to the drive motor.

3.Reducing Maintainance Cost

Unlike the type that uses dedicated roller which takes time to procure, you don’t need to have spare parts because it uses commercially available reasonable tires.

4.Space Saving

The width can be narrowed because lathe dog and drive transmission parts are not required.

5.Energy saving effect

In a typical shaft drive winder, the torque of the drive shaft increases as the drum flange diameter increases, therefore larger motor torque is required.

In the tire drive type, the force acting in the tangential direction on the outer circumference of the tire becomes the winding force directly, so the winding force does not change even if the outer diameter of the drum flange increases and the motor capacity can be reduced.

Ex.)when using two types of flange diameter φ2100/body diameter φ1050 and flange diameter φ1500/body diameter φ750 with condition of the winding speed 200 m/min and the winding tension 100 kg, the motor capacity is 15 kW for the shaft drive type, while 11 kw for the tire drive type.

6.Application to Brake Supply Stand

It can also be applied to a brake-type supply stand by replacing it with the torque mode of the drive motor or powder brake.

The disturbance due to backlash of the lathe dog pin and hole can be improved.

7.Additional Function

By extending the tire pushing stroke, it can be used as a push-out device during drum unloading, eliminating the need for a push mechanism that uses a separate power source such as an electric or hydraulic.

Note: Depending on drum material, flange shape and wire tension, tire drive system may not be suitable.